Testbed Brno

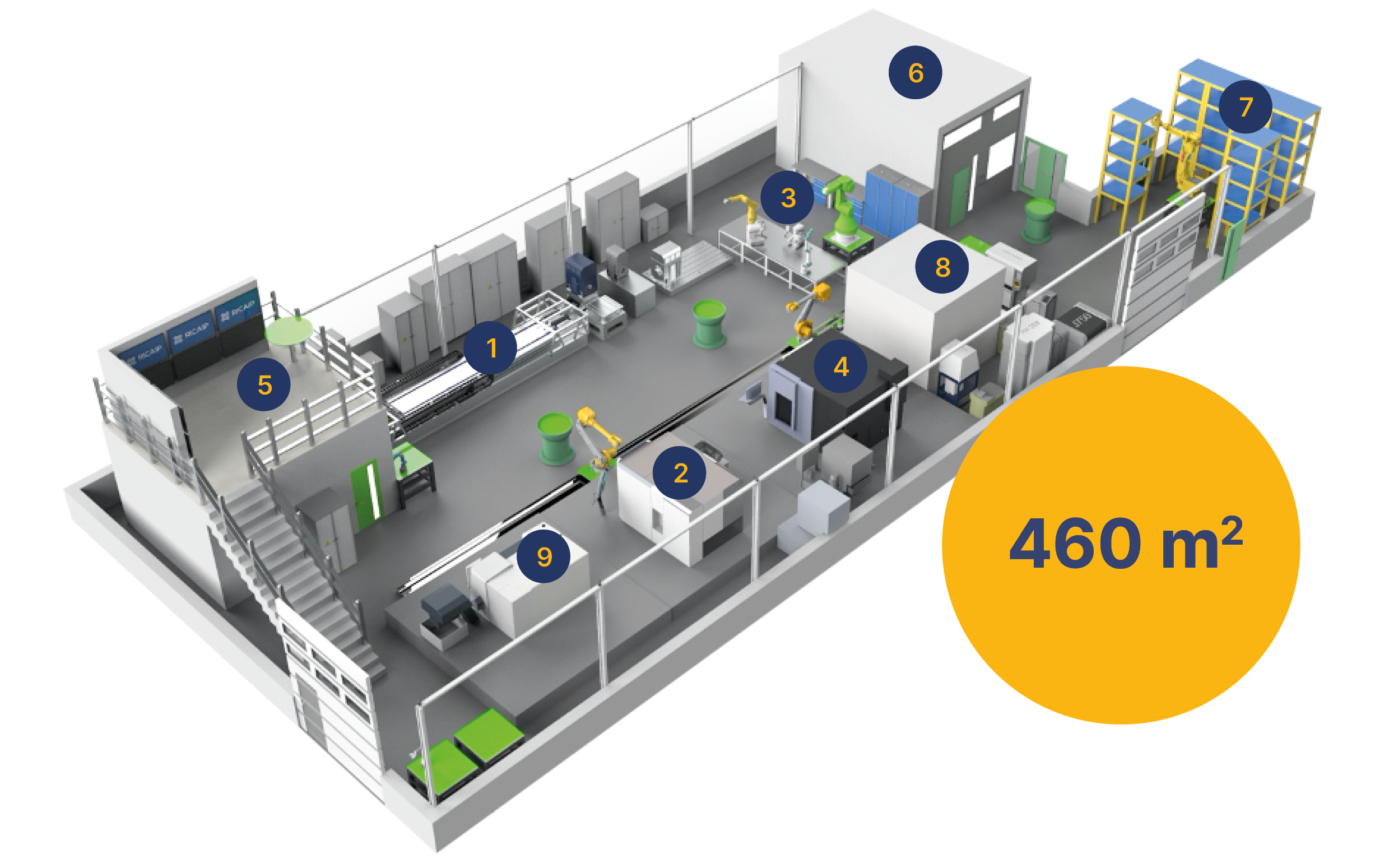

Brno testbed is located in an industrial hall within the Brno University of Technology campus and has been operational since november 2022.

- Dynamometers for industrial linear and rotational actuators

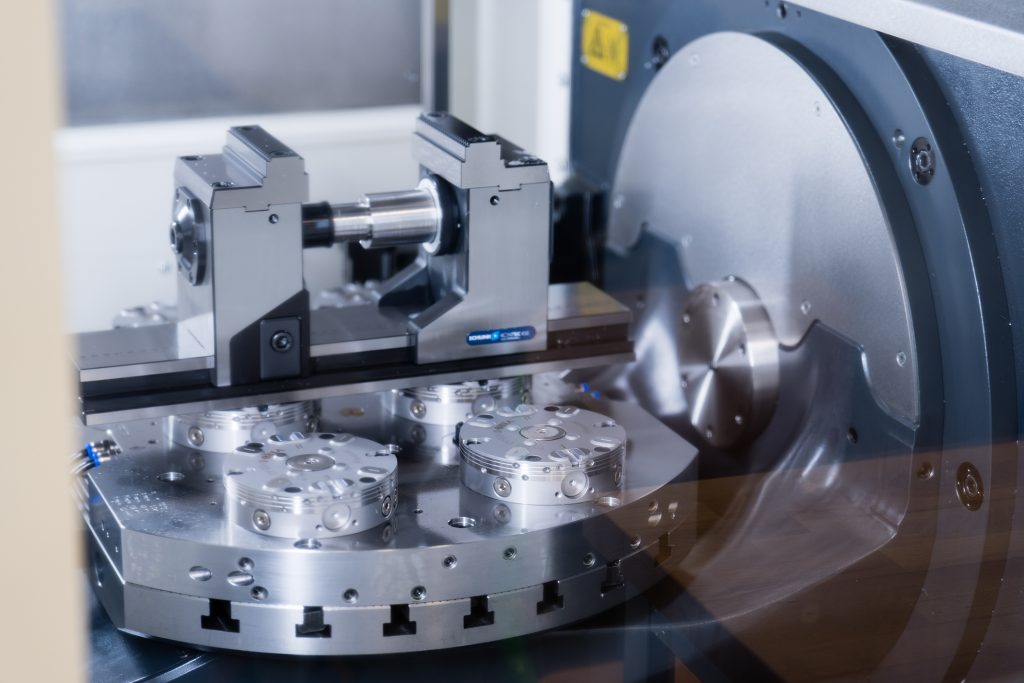

- 3-axis machining center

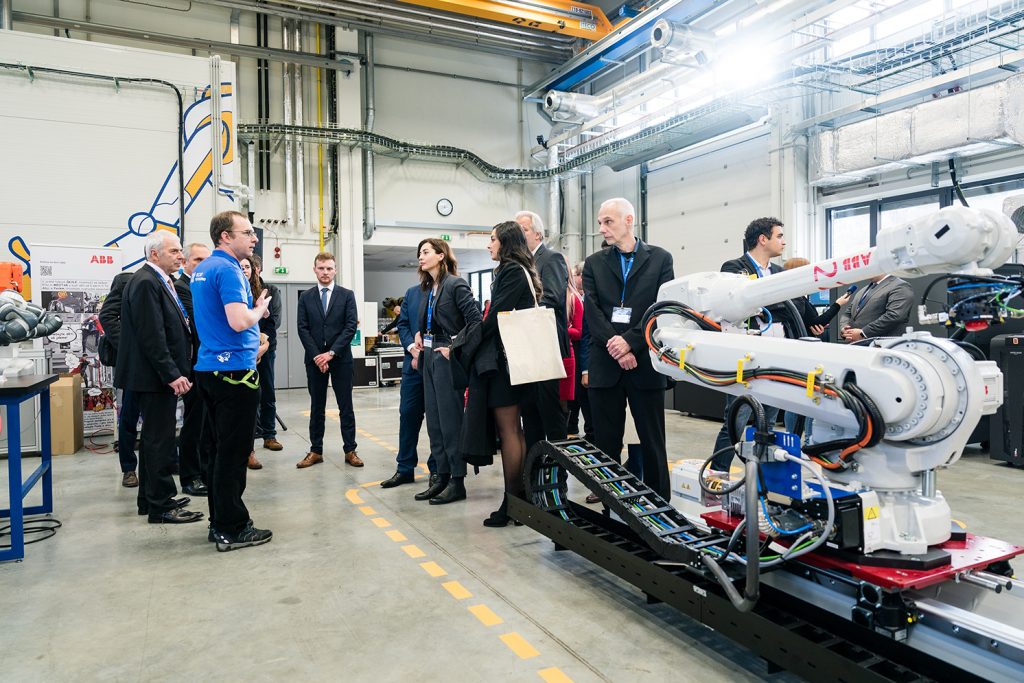

- Assembly line with collaborative robots

- 5-axis machining center

- AR/VR

- Precise measurement of dimensions

- Robotised warehouse

- Laser cutting/welding

- Turning machine

About

The testbed is managed by the Central European Institute of Technology (CEITEC BUT) and the activities of multiple teams within the BUT are executed here. The testbed infrastructure will be available for research & development, teaching & training activities, demonstrators and experimental production. It will be available to academic teams and industrial partners. During the start-up phase, the testbed will be used in many large-scale international projects in the field of Industry 4.0 and automotive technologies. The Brno testbed is connected to the regional innovation ecosystem oriented toward machinery and production technologies.

Equipment

The hall is equipped with a precise optical localisation system and provides enterprise-level SW solutions for products and production line design, simulation and operation, as well as a state-of-the-art automation network. Besides these production technologies, there is unique equipment for the development and testing of high-performance rotational drives (up to 250 kW power) for industrial and automotive applications and linear motor drives (up to 100 kW power).

Use Cases

The purpose of the testbed is to provide a testing environment that is close to real industrial conditions.

Many use-cases are considered:

- Data exchange in geographically distributed production systems.

- Collaboration human-robot-machine and interfaces.

- Combination of additive (3D printing) and subtractive (machining) processes.

- AI-based diagnostics, fault prediction and fault mitigation for industrial drives, mechatronic systems and production machines, vibro-diagnostics.

- IoT, sound/noise/vibration sensors, sensors networks.

- High-performance and highly reliable rotational and linear drives/powertrains in industrial and automotive applications.

Research Focus

Flexible Manufacturing Systems

- Additive/subtractive technologies combination

- Flexible transport systems – AGVs, AUVs, mobile manipulators

Human-Machine and Human-Robot Collaboration

- AR/VR technologies, precise localization and navigation in industrial environments

- Remote monitoring, visual telepresence

Machines and Mechatronic Systems

- Diagnostics and sensors for predictive maintenance

- Vibrodiagnostics, acoustic holography, acoustic emission

- Advanced automation and AI applications

Advanced Actuators

- Advanced rotary and linear drives for industrial applications

- Drive systems for electromobility

- Fault-tolerant drives, advanced drive control

- Diagnostics and monitoring

Contact

Prof. Pavel Václavek, Ph.D.

Research Group Leader, Research Area Coordinator

Prof. Luděk Žalud, Ph.D.

Senior Researcher

Brno Testbed Gallery