- This event has passed.

RICAIP at Hannover Messe 2025

March 31, 2025 – April 4, 2025 UTC+1

Part of the DFKI Booth | Hall 2, Stand B32

Hannover Messe is one of the largest and most important international trade fairs focused on industrial technology. Held annually in Hannover, Germany, it attracts thousands of visitors and exhibitors from around the world. The fair showcases innovations and trends in areas such as automation, digital manufacturing, artificial intelligence, energy solutions, industrial robotics, and other key technologies shaping the future of industry. It is an ideal platform for networking, exchanging knowledge, and presenting new products and technologies. Participants, ranging from small startups to global corporations, have the opportunity to establish business connections and gain insights into the latest developments in the industrial sector.

At Hannover Messe 2025, RICAIP will present a fully functional demonstrator showcasing the fundamental principles of flexible production using a miniaturized manufacturing cell as a part of the DFKI Booth at Hall 2, Stand B32.

AI for Automated Modular Production: Cooperative robotic production cell for modular retrofitting

To stay competitive in dynamic markets, manufacturing companies must adapt flexibly to changing production conditions and objectives. Modular manufacturing concepts enable the production process to be divided into individual, automated production steps without manual programming or configuration.

The European research project RICAIP (Research and Innovation Centre on Advanced Industrial Production) introduces a fully functional demonstrator that shows the fundamental principles of flexible production using a miniaturized production cell. The cooperative system, which consists of two KUKA robots – one stationary and one mobile – autonomously dismantles various types of electric batteries, replaces specific components, and assembles still-usable battery modules into new units. These can be repurposed as large stationary batteries for households or businesses, for example.

The demonstrator combines various AI technologies, such as machine learning and computer vision, with collaborative robotics, network communication, edge computing, and classic automation technology. The centerpiece is the automatic planner, developed by project partner CIIRC at the Czech Technical University in Prague. The planning software compares available resources with the machine functions and independently creates the production sequence – without manual programming or configuration. Moreover, the planner is integrated in an industrial Manufacturing Execution System developed and operated by T-Mobile.

The modular structure of the robotic production cell, the seamless integration of individual production machines, and the dynamic, machine-based rescheduling of production steps make this concept unique. The demonstrator serves as proof of concept for the automated retrofitting of multi-component products and can be transferred to different product types.

Meet the Researchers

Pavel Hradecký

Team Leader, Researcher

RICAIP Testbed Prague

CIIRC CTU

Jiří Štefan

Researcher

RICAIP Testbed Prague

CIIRC CTU

RICAIP Testbed for Industry 4.0

Testbed is an experimental infrastructure of the RICAIP Industrial Testbed Core. The backbone of the RICAIP Centre, located at the CIIRC CTU in Prague, Czech Republic.

It is a unique research infrastructure for the development and testing innovative solutions for advanced and fully integrated industrial production and processes for smart factories of the 21th century.

It is a core asset for the exploitation of results of multiple research projects dealing with Industry 4.0, robotics, and industrial AI. The latest technologies are designed for research and development of applications for industrial practice.

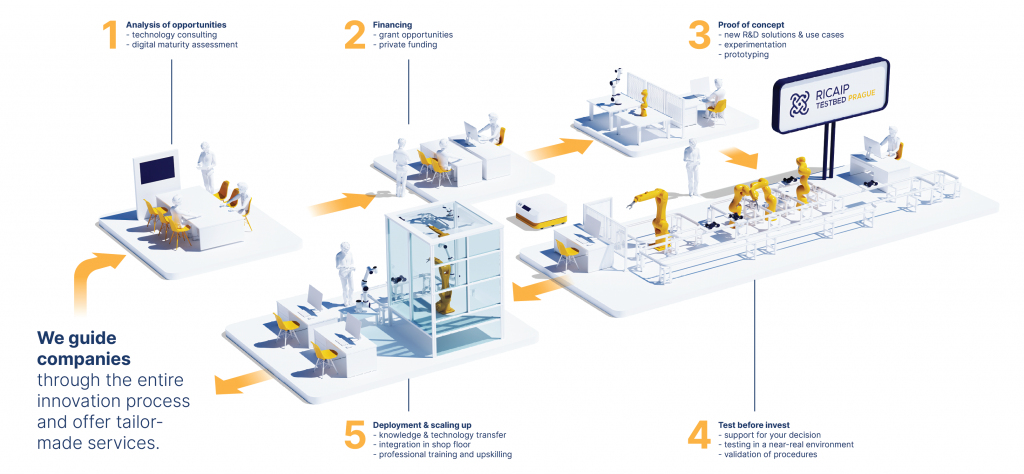

What We Offer to Companies – Small, Medium, Large, and Start-Ups

- We assist modern companies with AI-based innovations by providing tailored solutions using our own and our partner teams’ capacities and expertise.

- Our services cover the entire innovation cycle: Whether you’re addressing a challenge in any stage of digitalization or implementing AI into your operations, we’ll find the right solution for you.

- Our experts will support you with development, testing, financing, implementation, and training of technical staff.

- We validate processes and their feasibility through simulations and virtual commissioning, enabling us to scale solutions and demonstrate how they will work in real-world operations.

- We provide various solution options based on required production capacity and other parameters.

- Our services help manufacturing companies overcome numerous challenges and ensure long-term competitiveness.

Available Resources

- Infrastructure: Access to our testbed and partner testbeds within the RICAIP center, equipped with state-of-the-art hardware and software.

- Advanced Technologies: The latest technologies and methodologies.

- International Expertise: Access to academic and industrial experts in AI, robotics, and other deep tech fields.

- Data and Algorithms: Datasets, experimentation, and algorithms to develop optimal solutions.

- Training Programs: General, specific, and highly specialized programs in digital technologies.

- Funding Opportunities: Access to grants and other funding options.

- Tailored Services: Custom services for small and medium-sized enterprises through projects focused on AI and new technologies, such as EDIH CTU, AI-MATTERS, AIRISE, EIT Manufacturing, and more.

Through our partner ecosystem, you can also gain

- Digital Maturity Assessment

- Consultation and Digitalization Planning

- Access to New Technologies

- Long-term Financing

Why Collaborate With Us? We Guide You Through the Entire Innovation Cycle

- With our support, you gain expertise from our team and renowned partner organizations across Europe for safe navigation in new technologies.

- You can prototype and experiment with concepts and test them in a near-real environment using our equipment and technologies within the most advanced research infrastructure in Prague and other RICAIP testbeds.

- Test specific solutions before implementation without disrupting production.

- Improve and optimize your manufacturing operations.

- Leverage our strong international connections to find partners in the Czech Republic and abroad for further development and projects.

- Our solutions enable you to respond flexibly to market changes.

The Testbed Team is Here for You

Dr. Pavel Burget

Director of RICAIP Testbed for Industry 4.0

CIIRC CTU in Prague