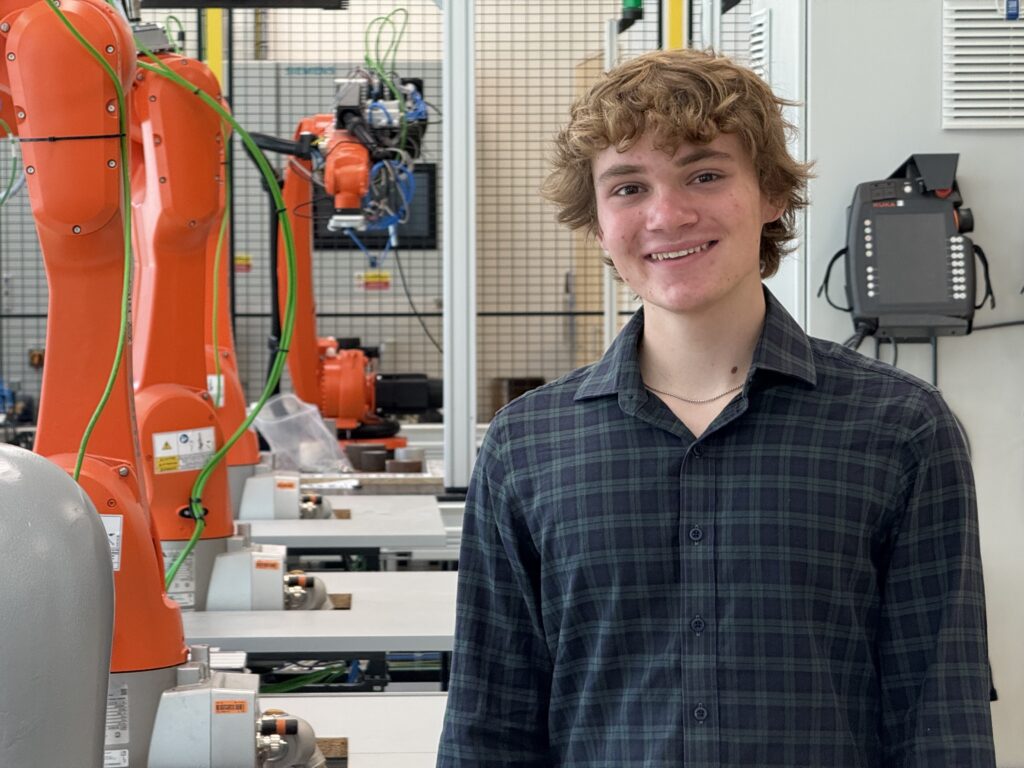

Nick Doing, an aerospace engineering student at Cal Poly, spent his summer immersed in hands-on robotics and technical design projects as an intern at the RICAIP Testbed Prague at CIIRC CTU, working under the guidance of Tomáš Jochman’s team.

With his combination of skill and curiosity, Nick engaged deeply with our projects, tackling difficult problems and offering thoughtful ideas. It’s been a pleasure to work alongside such promising young talent, and we trust this role has given him valuable experiences to support his education and ambition to study abroad.

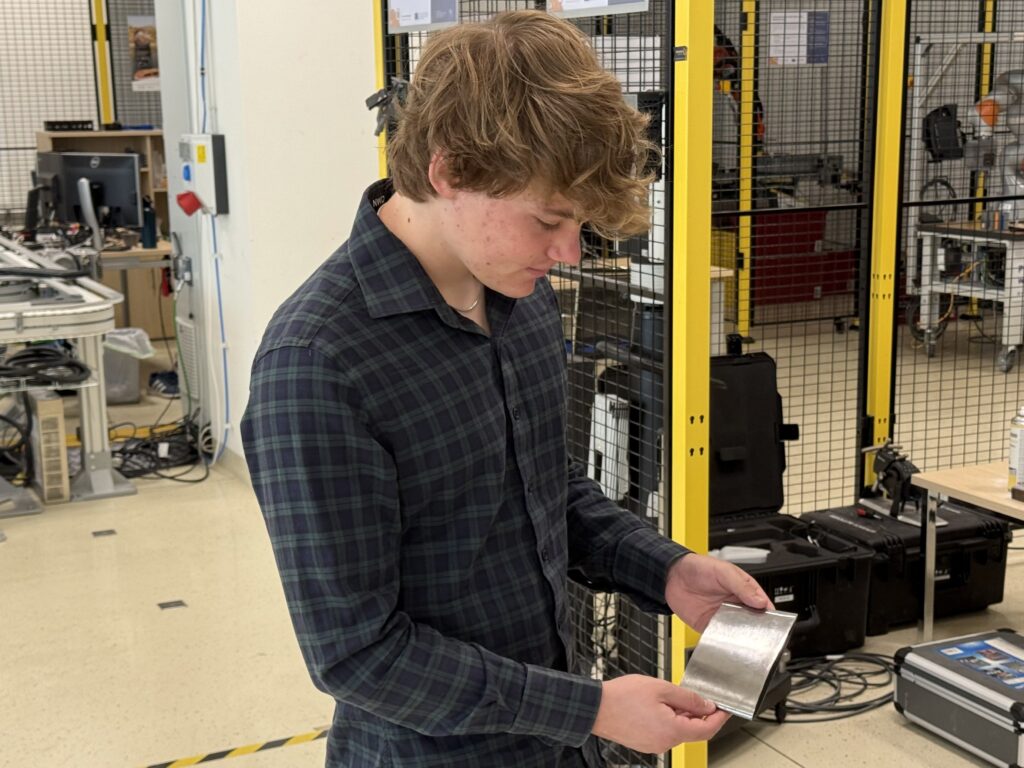

Nick’s summer at the Testbed put him at the heart of automotive manufacturing innovation, where he turned design concepts into production-ready components. As an intern, he worked hands-on with CAD modeling, topology optimization, and metal 3D printing creating and refining models to meet precise industry standards. From collaborating with engineers on specifications and function, to testing designs for manufacturability, he navigated the full product development cycle. Immersed in the fast pace of the automotive sector, he not only sharpened his technical skills, but also developed a keen understanding of how precision, collaboration, and creativity drive progress on the factory floor.

What Was Nick’s Experience Like at the RICAIP Testbed Prague?

Could you describe your experience working within a team at CIIRC CTU, specifically at RICAIP Testbed Prague? How did you find collaborating with colleagues from different backgrounds and countries?

I thoroughly enjoyed working as a part of this team. I was welcomed and felt like a valuable member from day one. With our diverse backgrounds and experiences we were all able to contribute unique ideas to our project, improving the performance. Not only were we coworkers but I truly consider my teammates friends. Depending on the day we would be exploring the city, playing tennis, or trying new restaurants (after getting our work done of course).

Can you describe for us the project you were working on and the tools you used to complete it?

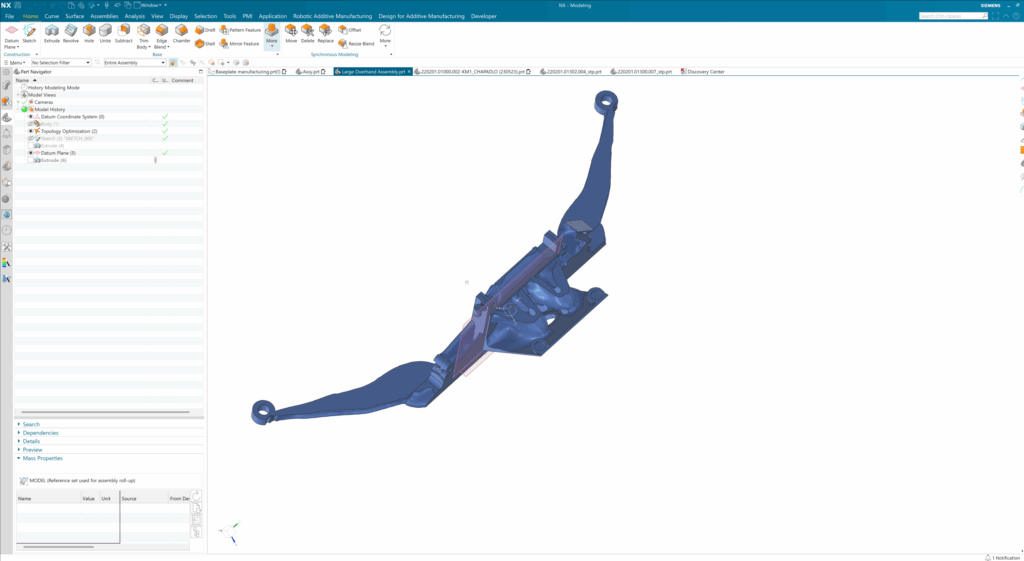

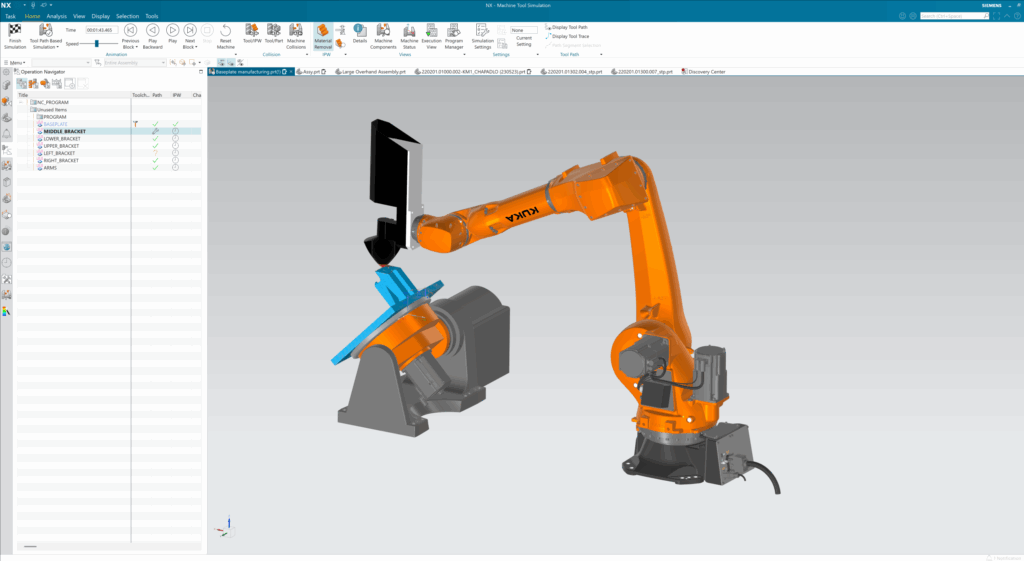

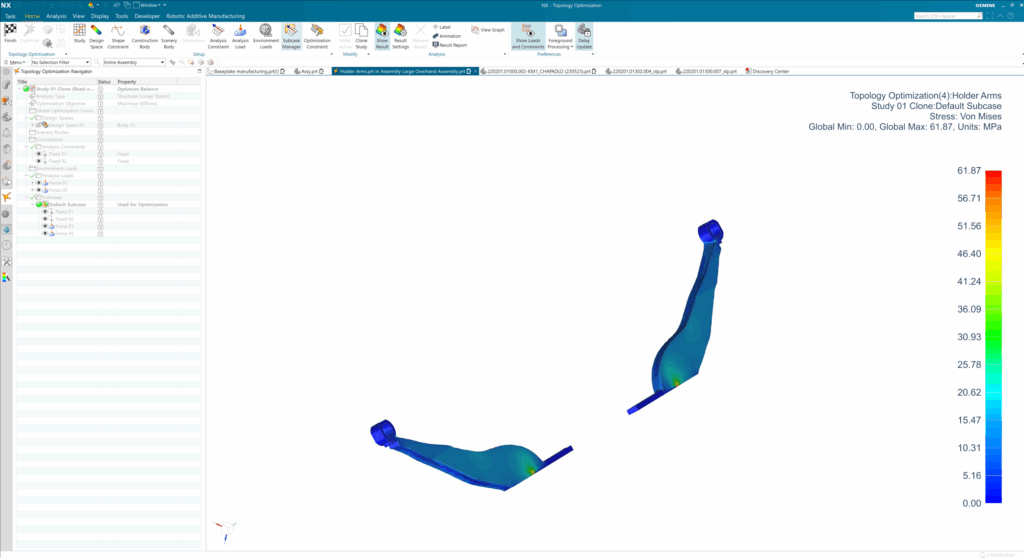

One of our customers, with an existing manufacturing line, had problems with overloading robots. As a solution, I was involved optimizing a gripper’s features such as its weight, shape, design and mass. To reduce mass but retain the necessary strength for the gripper mechanism we used an algorithm called topology optimization. This algorithm takes the forces and constraints applied to a body and adds material where the stress is high and removes material where the stress is low. This results in natural, tree looking structures. The real trick is to set up and keep tweaking the model until you get results that you like.

Due to the unique shapes produced by the algorithm, the only option for production is additive manufacturing. We used a 8-axis laser deposition metal 3D printer to produce the part. This came with its own set of constraints and challenges. We used a digital twin of the 3D printer to generate toolpaths and simulate manufacturing. While generating toolpaths it was necessary to continuously go back and tweak the settings and the original model until we were able to get something that was safely manufacturable.

I was tasked with a side project as well; as I learned basic skills in the visualization software Paraview then created a lab-specific tutorial on how to connect this software to the Nvidia Omniverse which is used heavily in our lab.

How were you able to apply the knowledge you gained at school to the practical challenges you faced during your internship, especially in CAD design and robotic systems?

My studies gave me crucial foundational skills such as numerical analysis, statics, dynamics, materials science, coding, basic CAD modeling, and basic manufacturing techniques. I then harnessed these foundations into applicable skills such as topology optimization and metal additive manufacturing techniques. There was definitely a learning curve, but I had the tools and resources I needed to be successful and my supervisors and colleagues were more than willing to help me out.

As a student from the United States, how did you perceive the atmosphere? Were there any particular challenges or advantages?

Coming from the United States, I didn’t experience too large of a culture gap. There were small differences, like how people took their coffee, but I think the overall work environment was similar.

“What I did find unique and amazing was the work culture specifically at our lab. Even as an undergraduate intern, I feel like I was treated with respect and as an equal.”

What I did find unique and amazing was the work culture specifically at our lab. Even as an undergraduate intern, I feel like I was treated with respect and as an equal. Overall, the culture was productive and understanding. It seemed like everyone was willing to help with anything. Moving to a new continent, I was a little bit nervous at first. However, that feeling quickly subsided when I was invited to play badminton and beach volleyball in my first week. Through work I quickly gained a network of friends which I am deeply grateful for.

While running your projects, to what extent were you given the freedom to contribute your ideas and make decisions?

Usually, I was provided with a problem and some resources to help me solve it. This involved lots of personal growth as I learned the skills to complete the task.

During this time I was free to make design decisions I thought were necessary for the success of the project. Once I reached a road block in my progress, or needed input on a big decision, I was able to meet with my supervisors. I would present my progress and we would brainstorm together on how to move forward.

I would follow their lead but they always made sure my voice was heard; They explained their thought process so I would always know why I was doing what I was doing.

Based on your experiences, would you recommend this internship to other students interested in robotics and mechanical design? Why or why not?

“The skills I needed to learn were directly applicable to my future career.”

Yes! During my experience in the Testbed I experienced a great combination of independence and guidance. My supervisors were focused on giving me projects that would develop me as an engineer and the career path that I want to follow. The skills I needed to learn were directly applicable to my future career.

How has this internship shaped your thoughts about your future studies and the specific areas within robotics or mechanical design you might want to focus on?

As an aerospace engineering student, I think experience with robotic manufacturing and topology optimization will set me apart in my future career. More often than not, in aerospace projects there are no people to carry out the mission.

Every task must be carried out through robotics. For example, if there is a probe mining an asteroid and it needs to turn raw material into parts, robotic additive manufacturing is one of your only options. Another important factor is mass. The heavier something is, the more energy and thus more money it takes to get your project to the desired orbit. Learning topology optimization techniques has given me a strong weapon in the fight against mass. With these learned skills, it sets me up in a great position to pursue a career in aerospace robotics.

Photographs by Tereza Pospíšilová for RICAIP Testbed Prague