The article was originally prepared by CEITEC BUT and published by Vseoprumyslu.cz, Sciencemag.cz, and Vedavyzkum.cz.

Imagine hearing an unusual sound from your car as you start driving. You might sense that something is wrong even before it actually breaks down. Now imagine that an industrial machine can listen to its own sounds in a similar way – and with the help of artificial intelligence, it can tell how long it will continue to operate without failure.

This is not sci-fi. With the computing power of the supercomputer at the CEITEC Brno University of Technology, it was possible to train an entirely new artificial intelligence model that can predict, based on sound, when a machine will stop functioning properly.

The Czech startup Neuron Soundware has developed a new way to more accurately predict the lifespan of industrial equipment using sound analysis and AI. In other words, thanks to artificial intelligence, it has enabled machines to “speak” about their own future. The resulting technology has the potential to change how companies plan maintenance, save costs, and prevent production outages. At a time when every minute of unplanned downtime on a production line is measured in thousands of euros, this capability becomes an undeniable competitive advantage.

The development of the new artificial intelligence model was led by a team headed by Jan Tožička, Head of the Machine Learning Team at Neuron Soundware. Tožička studied artificial intelligence at the Faculty of Mathematics and Physics of Charles University, focusing on neural networks and multi-agent systems, and later continued his studies at the Czech Technical University in Prague, where he worked on distributed machine learning and data mining. He also worked as a researcher in the field of multi-agent systems and spent several years in London designing AI algorithms for drone fleet control. Since 2018, he has been leading the development of algorithms for industrial diagnostics based on acoustic analysis.

“Our goal is for the machine not only to report when something has gone wrong, but to warn in advance when a failure is likely to occur. This is the key difference between reactive and predictive maintenance,” explains Jan Tožička.

Thanks to the European AI-MATTERS network, the research made use of cutting-edge technology and testing and experimental facilities (TEF) with fully subsidized service costs. Pavel Václavek, coordinator of the research program in Technical Cybernetics, Instrumentation, and System Integration at CEITEC BUT, states: “Here at the RICAIP Testbed in Brno, we can provide companies that have an innovative idea but lack the necessary equipment with our entire scientific infrastructure to verify the functionality of their concept. We can set up the entire experiment on our machines, which faithfully simulate an industrial environment.” CEITEC BUT has a wide range of industrial equipment, and a particularly attractive feature is the possibility to work with the High-Performance Computing cluster, a supercomputer for very demanding tasks.

This is a clear example of how European scientific infrastructure helps accelerate the transfer of research into practice and strengthens the competitiveness of companies. Such collaboration also demonstrates that the synergy between academia and industry can deliver practical results in a relatively short time.

When a machine speaks like a human

Neuron Soundware is based on the principle that, just as language models (such as ChatGPT) can predict what comes next based on text, models can be “trained” to anticipate machine behavior from their acoustic history. If a machine starts behaving differently – producing a different sound, higher vibration, or longer silence – it may signal an impending failure.

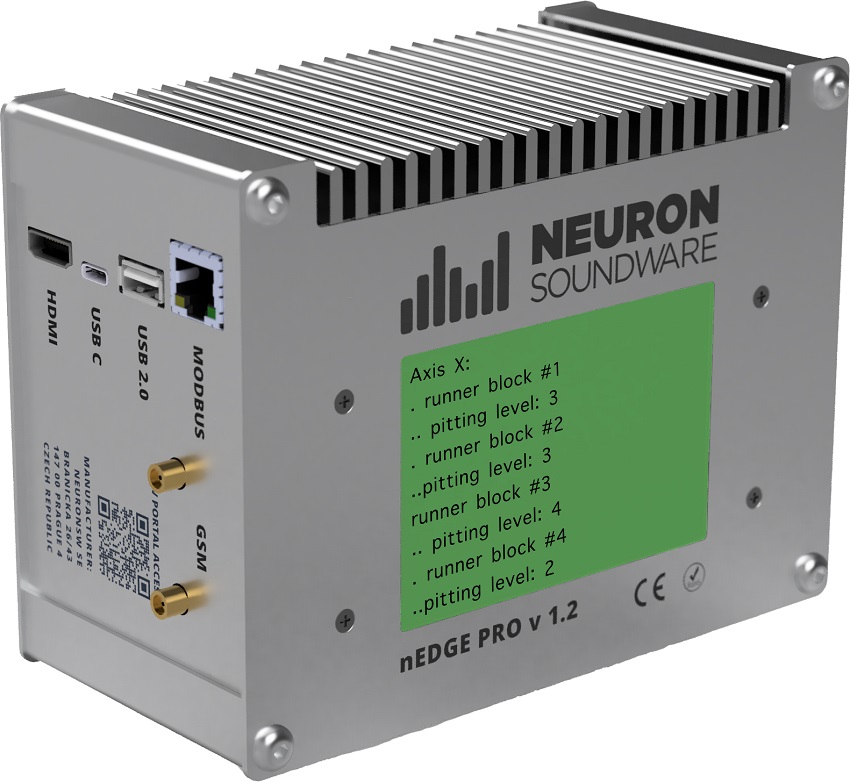

The advantage is that the system does not rely on a single type of data – in addition to microphones, it also uses vibration and temperature sensors. Thanks to edge computing technology (processing directly on the nEdge device), part of the analysis takes place right at the machine, ensuring a rapid response even in environments with limited internet connectivity. This provides reliability even where stable cloud access is not possible – for example, in heavy industry, mines, or remote manufacturing plants.

The latest nEdge PRO device functions as a small supercomputer located near the machine. It can simultaneously monitor data from dozens of sensors – from vibrations and sound to temperature and fluid flow – and, thanks to the built-in Nvidia Jetson Orin Nano chip with up to 40 TOPS of processing power, performs advanced analyses immediately on-site. This allows companies to obtain results within seconds, without waiting for data to be transmitted to the cloud, enabling faster responses to failures and higher production reliability.

The team collected sound recordings from dozens of types of machines (e.g., compressors, engines, pumps, etc.) and hundreds of their components (bearings, shafts, spindles, etc.) – for example, from material machining, CNC machines, or electromechanical components in escalators or elevators in manufacturing plants, airports, and similar locations. These were selected sound sequences recorded throughout the entire operational lifetime of the machines, which we have been collecting over the past seven years.

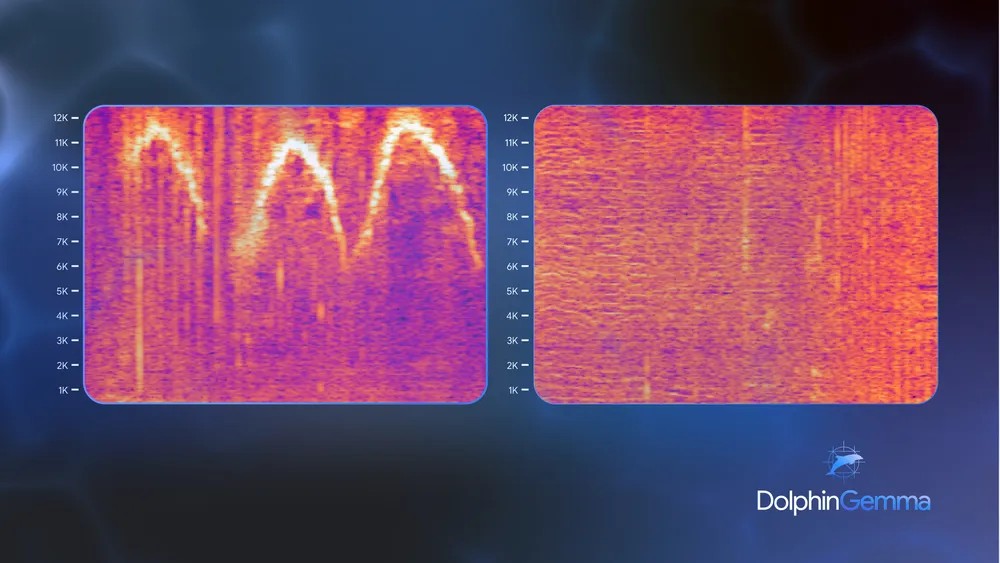

These recordings were then converted into approximately 33.6 billion so-called “sound tokens,” which work similarly to how language models handle words. The model was trained to predict which sound should come next. If something “doesn’t fit” – for example, if a knocking sound occurs instead of the expected buzzing – it flags this as a potential fault or sign of wear.

To help the model make sense of these sound “sentences,” so-called “special tokens” such as pause, maintenance, end, and others were added to the recordings. Thanks to these, the AI can better understand what is happening inside the machine and determine whether the equipment is operating normally or if something is wrong, and it can predict when a failure might occur – even before a human would notice it.

This is a similar approach to the one recently used by Google when training its DolphinGemma models to interpret dolphin communication.

Results: More accurate predictions and significant improvements

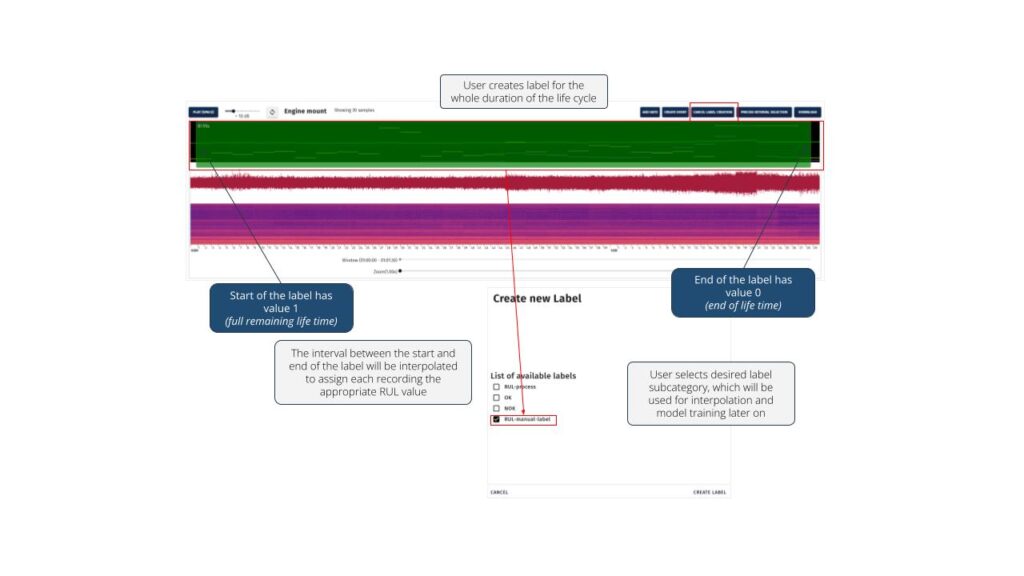

The team made the most significant progress in predicting the remaining useful life (RUL) of machines. By having the model work with the entire context of the machine’s operational history – rather than just the current state – it was possible to significantly improve the accuracy of its estimates.

The error rate has decreased to just 5–15% of the original values, which in some cases represents up to a tenfold improvement compared to previous methods. This breakthrough allows for better planning of maintenance interventions, minimizing downtime, and more efficient use of technical capacities. Additionally, the system has been optimized to operate on devices with limited computing power, significantly expanding its practical applicability in real-world operations.

In classification tasks (e.g., recognizing the current state of a machine or a specific type of fault), the new model was able to identify sounds based on just a few minutes of labeled data. Previously, similar classification required hours to tens of hours of labeled data, which for a new client project reduces the time and cost of data preparation by up to 95%.

Improvements were also seen in anomaly detection, where the model achieved a 1.6% increase in correct detections while simultaneously reducing the severity of potential errors by approximately 15%. Even more importantly, it correctly identified eight anomaly cases that no other model had detected before. This demonstrates that the new model better “understands” machine sounds even in situations where precisely labeled data are not available – that is, where the AI must rely solely on its ability to perceive subtle deviations and fault patterns in operational noise.

What does this bring in practice?

Imagine you have a CNC machine in production that normally runs three shifts a day. According to the maintenance schedule, the bearings are replaced every six months, preventively – regardless of how much the machine has actually been used. However, Neuron Soundware’s new model can use sound analysis to detect that a particular machine is starting to behave differently after just four months: instead of a smooth buzzing, subtle vibrations and irregularities appear, indicating the onset of wear.

Instead of blindly replacing all machines according to the schedule, you receive a specific recommendation: “This machine will need attention in three weeks; the others do not for now.” The result? This is a crucial difference that can bring huge savings in practice – not only on repairs but also on production downtime. AI thus becomes a reliable partner for maintenance personnel – it listens to the machine, understands it, and alerts in time when intervention is needed.

The technology tested in Brno is already being used far beyond the scope of an academic experiment. In the energy sector, AI can detect partial discharges in transformers, while in manufacturing, Neuron Soundware’s acoustic models monitor the entire process in real time, tracking its progress and the quality of products. The technology is also used in crushing and grinding raw materials, enabling the process to stop precisely at the moment the desired quality is achieved. This ensures a consistent product while significantly saving time and energy.

Equally important is its deployment in everyday machinery that drives daily production – for example, pumps and compressors. These machines are among the most common sources of faults because they are exposed to high pressure and vibrations. Acoustic monitoring allows for early detection of cavitation in pumps or increased vibrations in compressors, which indicate bearing wear or imbalance. In practice, this means that faults can be addressed before they halt the entire production process.

Unplanned machine downtime is one of the biggest hidden costs for industrial companies – according to analyses, 80% of firms experience it every year, resulting in losses exceeding €35 billion annually. AI-based predictive maintenance can dramatically reduce these losses – up to 60% fewer failures and up to 35% lower production costs. The benefits are not only economic; thanks to reduced scrap and lower energy consumption, this technology also has a significant environmental impact.

And what’s next?

Just as we have taught machines to “speak” about their own health, the next step is to teach them to communicate with us. Already, in the nGuard portal, you can interact with an AI chatbot that not only understands the machines but can also recommend what actions to take next.

This technology, which just a few years ago belonged to the realm of laboratories and experiments, now helps keep production running – quietly, precisely, and proactively.