Flexible Modular Robotic Cell: Retrofitting Battery Modules

This is a scaled-down model of an autonomous modular factory that adapts to changing production conditions. In just a few square meters, we demonstrate the key principles of modern, flexible, and sustainable manufacturing of the 21st century. We combine cutting-edge technologies and processes: intelligent collaborative robotics, data communication via a 5G network, edge computing, AI algorithms, computer vision, and autonomous control. All this is showcased through two KUKA collaborative robots that, without human intervention, exchange components and perform retrofitting on used battery modules, demonstrated on a scaled model of an electric vehicle battery. In real applications, these battery modules can continue to serve as large-capacity stationary batteries for homes or businesses.

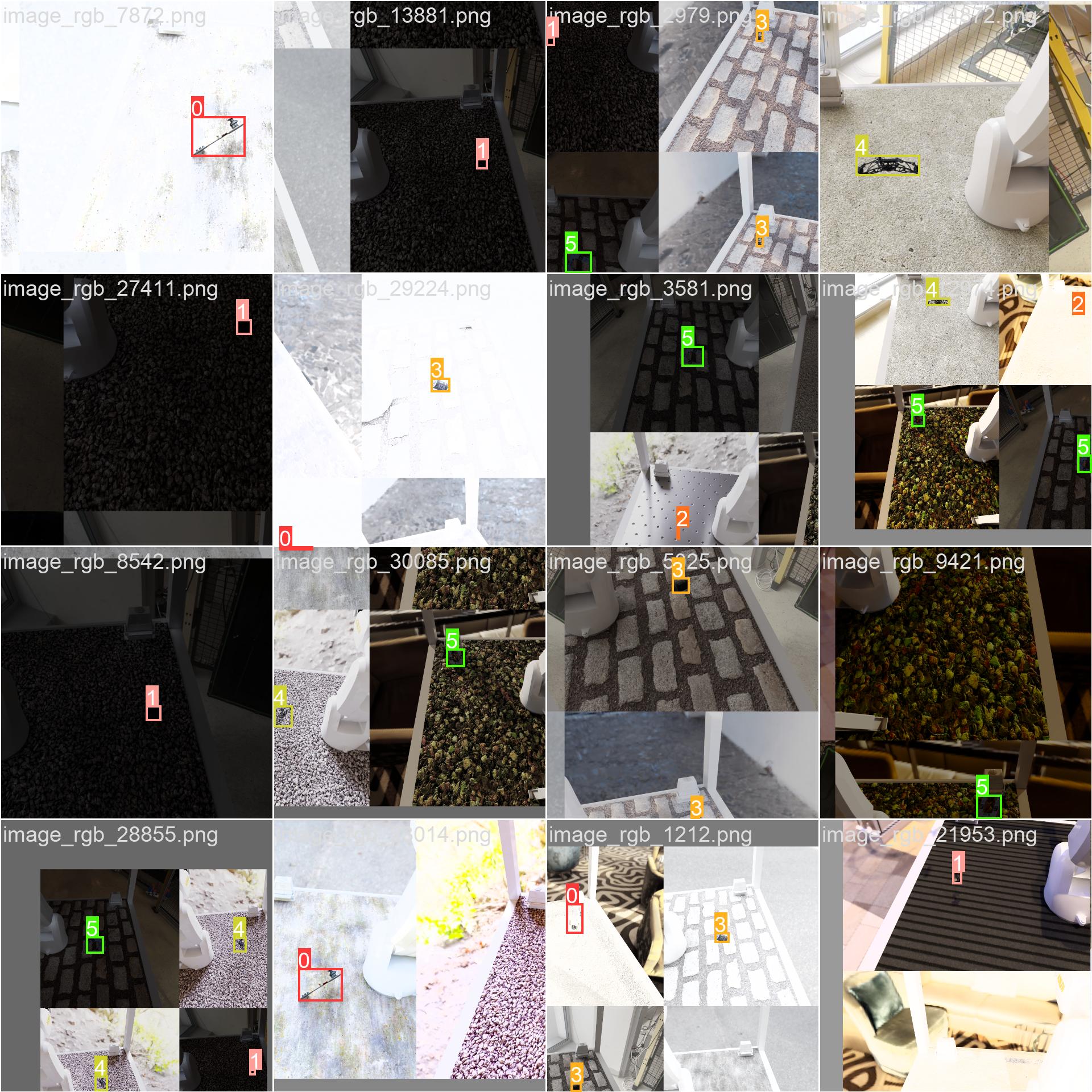

Industrial Metaverse: Autonomous Manipulation Robotic Cell

The industrial metaverse is essentially an extended virtual reality that allows for the creation of a digital twin of a physical factory, machines, and products. It enables optimization of production processes, acceleration of product development, and enhanced collaboration between teams and robots. We demonstrate its potential with an autonomous manipulation robotic cell featuring a KUKA robot, performing precise pick-and-place operations, driven by advanced 6D position estimation using computer vision. The cell is virtually operated in Siemens’ Tecnomatix Process Simulate with integration into Nvidia Omniverse, allowing AI model training for object recognition and manipulation, and automated generation of end effectors through 3D printing. It’s also available in VR.

Sustainable Manufacturing: 5G IIoT and Machine Data Collection for Energy Consumption Monitoring

Data is all around us, but how can we collect, analyze, and use it to boost manufacturing efficiency, reduce costs, and enhance sustainability? At our stand, you’ll see this in real-time thanks to a compact modular 5G IIoT system, integrating energy consumption data across our entire display. Data transmission occurs over a 5G SA private campus network, with continuous monitoring of the 5G signal quality. A new feature is the NB IoT technology for water consumption measurement using a compact flowmeter, ideal for battery-powered devices.

Robotic Beer Dispenser 2.0

Our new Robotic Beer Dispenser 2.0 is fully automated and ready for continuous, unattended operation. It can pour four beers simultaneously and is equipped with AI to adapt to its surroundings and optimize energy consumption. Thanks to sensor feedback, the robot can actively adjust its movements while pouring beer. Advanced data analytics intelligently manage cooling and predict failures. Age verification can be ensured through facial recognition, making subsequent purchases automatic. This dispenser represents a cutting-edge solution for sustainable and smart beverage service using the latest technologies.

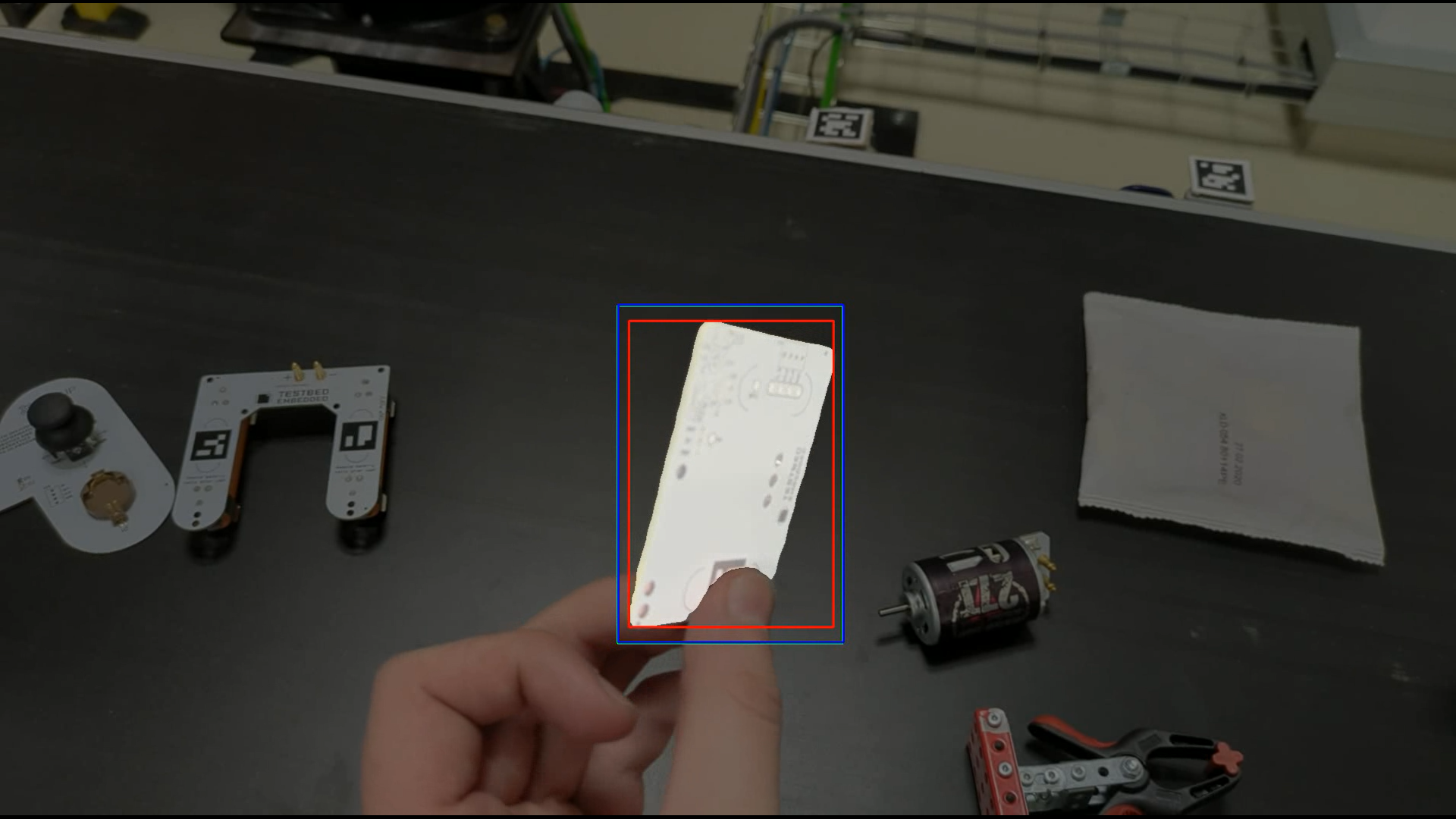

3D Object Reconstruction

We showcase how 3D object reconstruction aids in safely detecting objects for precise manipulation in unknown or changing environments. We developed an accessible and efficient device capable of spherical scanning using a standard RGB camera. The images are processed by our software into a 3D representation, allowing object detection, position estimation, and manipulation. We use an advanced 3D reconstruction algorithm that combines the power of computer graphics (Volume Rendering) and machine learning to create a 3D scene representation.