- This event has passed.

Researchers’ Night 2022 at Testbed for Industry 4.0: With all THE SENSES

September 30, 2022 | 17:00 – 22:30 UTC+1

Researchers’ Night 2022 – an event that, for one evening, brings life to hundreds of science buildings that no ordinary mortal can enter. Visitors pass through laboratories and lecture halls, experience exploding experiments, and learn about hot topics in depth. Everyone with a passion for science – children, adults, and seniors – is welcome. Meet our scientists and they will teach you to love science.

Researchers’ Night was initiated by the European Commission in 2005 and its mission is to show that science is not boring, but on the contrary is a source of interesting and fascinating phenomena.

One day a year, universities, research and development centres, science centres, and other places open with free guided tours, popular education presentations, workshops, experiments, science shows, music, and performances, amongst others, taking place. The aim of Researchers’ Night is to dispel myths about scientists as people locked in laboratories and to show the general public that they are “ordinary people” who do work for each of us, they can present it in an engaging way, and they can also have a good time.

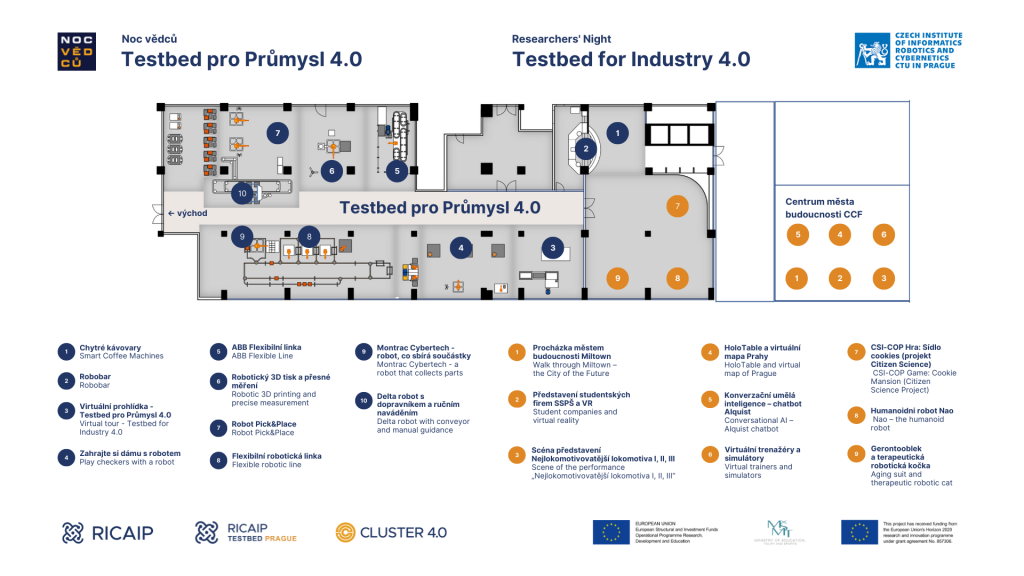

There are many interesting things to explore during Researchers’ Night 2022 at RICAIP Testbed for Industry 4.0 at CIIRC CTU:

1/ Smart Coffee Machines

Let one of the two automatic coffee machines serve you. Simply enter your preferences using your tablet or smartphone and the coffee machine will take care of the rest for you.

At the coffee machine station, you will be able to try out the various smart devices – order coffee from your phone, tablet, watch or even by voice command. You will taste and compare different types of coffee, we will offer cocoa or hot milk foam for the kids and you can also compete with us.

2/ Robobar

Robots that can tap beer like a skilled bartender. You can also order lemonades, coffee, alcoholic and mixed drinks. All you have to do is enter your request via the ordering tablet and remember your order number.

In addition to the two collaborative robots, the Robobar in Testbed for Industry 4.0 also uses the functions of other devices, including a liquor conveyor, fruit feeders, an ice feeder and more. It’s all connected via a common industrial communications platform.

3/ Virtual Tour at Testbed for Industry 4.0

Testbed for Industry 4.0, in which you are located, is also available in virtual form. You can explore the Testbed in both real and virtual reality and compare the differences between the two worlds.

Individual work cells, production lines and robotic workplaces are presented. In addition, technological functions for measuring, drawing, repositioning and more are demonstrated in virtual reality, all in 3D.

4/ Play checkers with a robot

Industrial robots can be fun! Do you dare to test your knowledge in a game like checkers against a robot that is programmed to predict the state of the gameboard for up to 9 moves ahead?

You can experience the interaction with an industrial robot and compare your strength in checkers with the algorithms of artificial intelligence by choosing between three difficulty levels.

5/ ABB Robotic Line

The workplace incorporates several technologies that contribute to flexible production. The conveyor trolleys are controlled independently of each other, allowing their movement to be adapted to the needs of the specific product they are transporting. In addition, it is possible to synchronise the movement of the trolley with that of the robot, allowing the robot to manipulate the part on the trolley without the trolley having to stop. The collaborative robot, which is part of the workstation, offers the flexibility to work with a human on a specific assembly operation and can react to the actual conditions and characteristics of the part being handled.

6/ Robotic 3D printing and precise measurement

Universal robotic workstation for 3D printing and precise measurement with the “Laser tracker”. We also have a digital model of the workplace, the so-called digital twin, used for simulating the 3D printing process, verifying paths and collisions. Using a touch probe that is connected to the laser tracker and the robot, we perform automatic calibration of the robot’s work table. During the 3D printing process, the position of the printing nozzle can be corrected by a corner reflector due to feedback from the laser tracker.

7/ Pick & Place Robot

Using artificial intelligence, the Pick & Place robot processes data through sensors and cameras to detect paper packages of Lego bricks. It autonomously detects the exact location in 3D space and plans the robot’s trajectory. Based on the classification, it selects packages of different sizes and sorts them into boxes. This robot can be used to automate logistics operations in manufacturing.

8/ Flexible Robotic Line

The core of Testbed for Industry 4.0 is an experimental robotic line with a conveyor. It is used to test the possibilities of so-called flexible distributed production. Customers can configure what they want their car to look like and the machines will build it for them. A flexible robotic line is a scaled-down model that allows easy assembly of customised products using automated planning methods. Small batches of products can be produced as well as piece production.

9/ Montrac Cybertech

Only few people realise that robots in production, such as those that quickly and flawlessly assemble a car every day, are precisely programmed and any deviation leads to a halt in production. The position of the part to be picked up by the robot is always fixed and precise. If a rack shifts or a part is not in the exact location, then an error will occur and the line will stop. Therefore, we will add a camera to the robot and it will be possible to take any part from the rack, regardless of the location of not only the rack but also the parts themselves.

10/ Delta robot with conveyor and manual guidance

Delta robots are used for applications where fast operations are required. This demonstrator is equipped with a conveyor whose pallets can be precisely tracked and the robot’s movements can be synchronized with those of the pallets. The robot can be equipped with a handle to perform what is called a “manual guide” to learn the trajectories to be performed during normal operations. It operates on an industrial 5G network and enables fast transmission of large amounts of data. Therefore, the integration of a neural network and computer vision could be implemented in the robot system.