Every company has a different story. Some companies are just now deciding whether to digitalize their first production line. Others already use AI for predictive maintenance. But they all have one thing in common – without partnerships and knowledge sharing, progress would be slow. Innovation doesn’t happen in isolation. It happens when scientists, tech companies, machine suppliers, and financial partners come together.

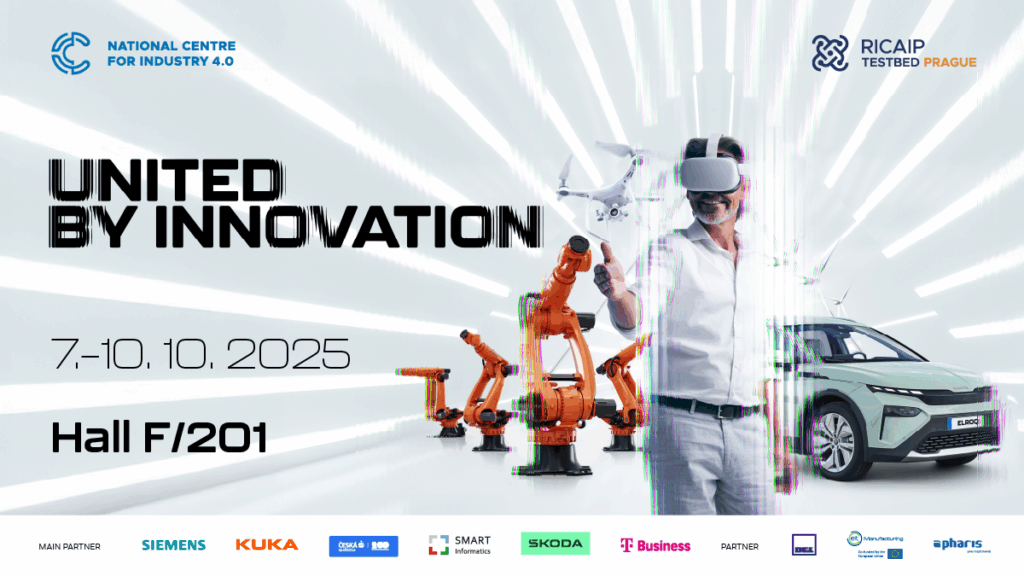

At the International Engineering Fair (MSV) 2025, taking place October 7–10 in Brno, this collaboration will be showcased in full force – as a new perspective for industry, energy, and services. At Hall F – Digital Factory, the „United by Innovation“ stand demonstrates that the Czech industry already operates a functional innovation ecosystem – connecting academia, technology providers, data, and financing. Presenting together at the stand are National Centre for Industry 4.0, RICAIP Testbed Prague, KUKA, Siemens, Česká spořitelna, Smart Informatics, Škoda Auto, T-Mobile, DEL, EIT Manufacturing, and PHARIS.

Perspective: Strategy & Financing

Even small innovations must prove their value – by solving real operational issues and bottlenecks, and by offering a clear return on investment. Success isn’t just about the idea – it requires a solid strategy and smart financing. Companies today combine internal resources with external funding – from private investors to well-targeted project grants – so they can implement new technologies without unnecessary compromises.

At the United by Innovation stand, experts from the Czech Institute of Informatics, Robotics, and Cybernetics at CTU (CIIRC CTU) will offer on-site consulting. Thanks to their participation in European initiatives like AI-MATTERS/TEF and EDIH CTU, they bring real-world experience with integrating digital technologies – including AI – into Czech manufacturing, startups, and SMEs. They guide firms through the full innovation cycle – from strategy to financing – and connect them with suitable technology suppliers,” explains Robert Keil, Director of the National Centre for Industry 4.0.

Česká spořitelna actively supports innovation, financial health, and a resilient business environment. At the stand, they will present how the Česká spořitelna Financial Group’s banking and advisory services – from investment and project financing to leasing, grant consulting, and ESG/energy advisory – help companies grow, innovate, and stay competitive. The bank will also showcase the Road Show for a #StrongerFuture – highlighting 9 future-oriented industries, breakthrough Czech innovations, and transformative projects reshaping both industry and everyday life.

EIT Manufacturing helps turn innovations into globally successful ventures. One example: Robotwin, a Czech startup that began as a master’s thesis by co-founder and CTO Megi Mejdrechová. Today, Robotwin has secured investments exceeding CZK 80 million. Its technology brings an easy-to-use programming system for industrial robots, particularly targeting SMEs that often lack programming staff. EIT supported the startup with proof-of-concept validation among industrial partners as well as financing.

Perspective: Digital Transformation of Manufacturing

Some companies already have a clear vision of what they need to innovate to gain a competitive edge. Others seek inspiration from proven solutions. But all of them need to consult their plans with experts.

At the stand, visitors can try out the MES system by PHARIS, explore production line digitalization directly with integrator DEL, or see the latest from KUKA, which is pushing the boundaries of automation. The new KRC5-2 control system, developed to ISO 10218 standards and cybersecurity requirements, together with the iiQWorks software, significantly shortens robot installation and commissioning times. The growing segment of mobile robotics is represented by the KMP 600P, offering greater flexibility, safety, and solutions to labor shortages in logistics. In cooperation with Siemens, KUKA will demonstrate how robots naturally fit into the wider ecosystem of industrial automation.

The RICAIP Testbed Prague team at CIIRC CTU addresses smart digitalization of manufacturing from multiple perspectives, with the main goal of making processes more efficient and precise. Imagine a production line producing thousands of different components daily. Each must be thoroughly inspected – manually, this would mean hours of monotonous work and a high risk of errors. RICAIP Testbed Prague will demonstrate a fast, reliable, and scalable solution combining state-of-the-art industrial cameras with proprietary machine learning algorithms to detect even the tiniest defects and classify parts. Thanks to multispectral data and lighting, defects invisible to the human eye can be uncovered. All of this is fully automated, ensuring only flawless components reach the customer.

We use both commercial and proprietary vision systems, trained on real production data. In our testbed, we develop 3D scanning and robotic bin-picking algorithms,” explains Martin Mikšík, RICAIP researcher. “Robots can locate and grip randomly oriented parts of various shapes. We’ll show that automation is now possible even in areas previously considered too complex.”

Private 5G networks are increasingly entering industrial operations. This year, T-Mobile introduces “localization,” enabling precise tracking of devices and assets – from mobile phones and 5G routers to 5G localization units attached to autonomous vehicles. The technology tracks movements in real time with ultra-low latency, finding applications in industrial automation, logistics, warehousing, mining, healthcare, and R&D.

Smart Informatics has developed a system enabling real-time video transmission from intervention sites – today already used by the Fire Rescue Service of the Czech Republic. Commanders gain instant situational awareness, enabling faster and more precise rescue coordination. The technology works across all connectivity types – from 5G to satellite Starlink – and often collaborates with drones. It also has potential for police, healthcare, defense, telemedicine, and remote surgeries.

Perspective: Resource Efficiency

Smart innovation requires smart resource use. The right solution can reduce electricity, water, and material consumption – all factors that directly impact production costs. Amid rising prices and supply uncertainties, resource efficiency is now essential to every innovation equation.

RICAIP Testbed Prague will show how data can uncover cost-saving opportunities. At the stand, visitors can explore how integrating diverse measurements – from electricity and water usage to network quality – creates a clear operational picture. With advanced IIoT devices, a private 5G network, and a new NB-IoT ultrasonic flow meter powered only by battery, real-time consumption can be monitored and optimized instantly.

This isn’t just about sensors or isolated tools – it’s about a holistic approach that turns raw data into strategic advantage. RICAIP supports companies where standard solutions fall short or don’t exist. Alongside integrating top-tier systems, they develop their own technologies tailored to end-user needs. Only complete data control enables companies to improve processes, cut costs, and use resources efficiently – making manufacturing both more competitive and more sustainable.

Siemens’ Simatic Energy Manager Pro is another data-driven solution – advanced software for comprehensive energy data management in companies. It provides automated collection, detailed analysis, and clear visualization of energy consumption data. This allows businesses to identify potential savings, optimize consumption, and significantly reduce operating costs. The benefits are already confirmed by recent references, for example, from the food industry.

We stand at the threshold of a new era, where the digital twin of industrial buildings is not only a technological leap, but a practical everyday tool. What comes alive today in real time with production data is only the beginning – the first step into a world where buildings have their digital counterpart and start to communicate with us. Every notification of increased energy consumption, every equipment status report, or maintenance plan is not just a number, but a story of how factories are becoming smarter, more economical, and more efficient. Škoda Auto is already demonstrating how this vision works on a large scale. Right now, it is writing a new chapter – an era where the digital twin of industrial buildings reshapes operations, energy use, and the very concept of facility management.

The Future Is Within Reach

The stories from United by Innovation partners show that Czech industry holds all the building blocks for real transformation: strategy and funding, digital technologies, and intelligent resource management. At the MSV 2025 International Engineering Fair in Brno, these perspectives converge – in Hall F, at Digital Factory stand No. 201. Come get inspired, talk to experts, and see firsthand how science and innovation are reshaping Czech industry, energy, and services.

More info on the exhibit and accompanying program:

https://www.ncp40.cz/udalosti/msv2025