RICAIP Prague testbed at CIIRC CTU is being equipped with new technologies but already now, it is open to welcome students for their summer 2021 internships. They can select from a long list of topics for their semester thesis, projects, or other forms of collaboration with the scientific team of the testbed.

Students from the second (and further) year of university with an interest in cybernetics, robotics, and informatics, can join our scientists for this summer full of R&D and topics focusing on the hot challenges of Industry 4.0. Our team of the Testbed for Industry 4.0 is searching for students who are eager to devote their time, ideas, and investigation in a near-real environment fully equipped with new technologies within the RICAIP centre.

In case of interest in some of the following topics, please do not hesitate to directly contact Pavel Burget, Director of the Testbed for Industry 4.0, CIIRC CTU:

- LEGO 6DOF industrial robot control

- Jetbrains IDE plugin for application deployment to Siemens Edge Hub

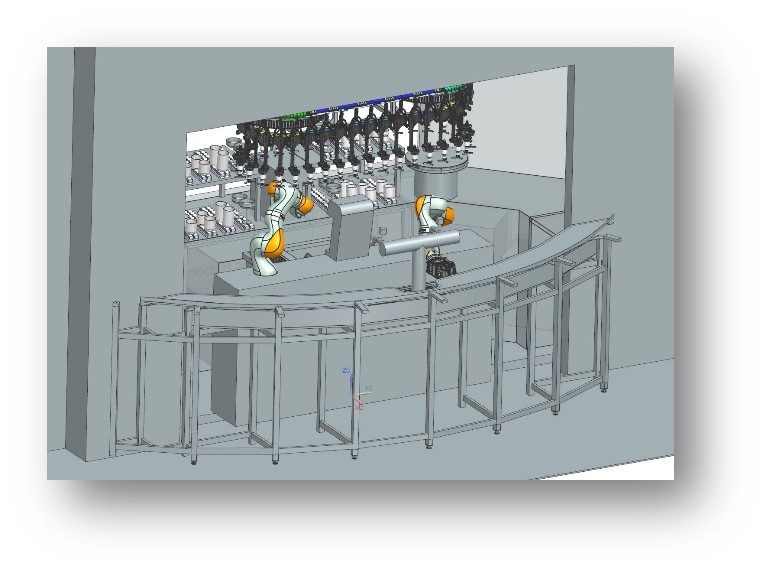

- Java developer for Robotic bar project

- Smart coffeemaker adaptation for Robotic bar project

- Laboratory industrial line test development

- Automatic grasping

- Development of OPC UA Debugger

- Dynamic modelling of a Delta robot

- Position control of a Delta robot

- Force control of a Delta robot

- Assistive robot for health care

- Precise measurement and real-time monitoring with Leica laser scanner

Summer 2021 internships topics

Title 1: LEGO 6DOF industrial robot control

| Title | LEGO 6DOF industrial robot control |

| Type | Summer job (with possible bachelor thesis extension) |

| Supervisor | Ing. Ondřej Novák |

| Possible start | Summer 2021 |

| Required skills | Python (advanced) |

Topic:

- Reverse engineering of LEGO Mindstorms program for controlling LEGO 6DOF robot

- Choose SW library of a framework with a focus on robot control. Klamp’t Python library is preferred.

- Implement the robot control in the framework – incl. Motor control, inverse kinematics, basic movements such as linear and point to point. Also focus on the safety of the application, e.g., the wires should not twist too much. It could also be extended by smarter control such as automatic pathfinding.

- Implement a specific network communication interface to control the robot (OPC UA).

Title 2: Jetbrains IDE plugin for application deployment to Siemens Edge Hub

| Title | Jetbrains IDE plugin for application deployment to Siemens Edge Hub |

| Type | Thesis |

| Supervisor | Ing. Ondřej Novák |

| Possible start | Summer 2021 |

| Required skills | Java (advanced), knowledge of Jetbrain’s IDE, basic Docker knowledge, computer networks |

Topic:

- Get acquainted with Siemens IEM and its way of deploying app work

- Get acquainted with Jetbrains API for writing for Jetbrains IDEs such as Pycharm and Intellij

- Write a plugin for Pycharm, Intellij (and possibly more) for building an app and deploying it into the Edge Hub. Use CLI program provided by Siemens to communicate with the server.

Title 3: Java developer for Robotic bar project

| Title | Java developer for Robotic bar project |

| Type | Summer job or internship |

| Supervisor | Ing. Ondřej Novák |

| Possible start | Summer 2021 |

| Required skills | Java (advanced), knowledge of Jetbrain’s IDE, basic Docker knowledge, computer networks |

Topic:

- Help to implement the given microservice for our Robobar project. This could be, for example, a REST API for receiving orders or maintenance, a communication interface based on RabbitMQ, a digital twin service, planner service, or device-control service.

Title 4: Smart coffeemaker adaptation for Robotic bar project

| Title | Smart coffeemaker adaptation for Robotic bar project |

| Type | Summer job or internship |

| Supervisor | Ing. Ondřej Novák |

| Possible start | Summer 2021 |

| Required skills | Python or Java, knowledge of OOP, knowledge of basic electronics is an advantage |

Topic:

- Implement software that bridges PLC and a coffee machine for our use of the machine on the robotic bar. The coffee machine supports open TCP/IP protocol for communication. It is important for the software bridge to be stable and well tested so it can run for extended periods of time. It also may interact with additional sensors (such as water level), if it would be necessary for the adaptation. Use OPC UA protocol for communication with the PLC.

Title 5: Laboratory industrial line test development

| Title | Laboratory industrial line test development |

| Type | Thesis |

| Supervisor | Ing. Ondřej Novák |

| Possible start | Summer 2021 |

| Required skills | Python (advanced), basic knowledge of S7 PLC programming (for debug) is an advantage |

Topic:

- Get acquainted with Montrac line in Testbed for Industry 4.0

- Implement automated „unit tests“ for individual components and subcomponents

- Individual robots and their operations

- Conveyor

- PLC

- Implement automated integration test for the whole production line

- Implement a control and reporting mechanism for tests, that will allow user to easily see unsuccessful tests, the reason they failed, and a way to re-run the tests. I.e., implement a central program that will guide the user through the testing process.

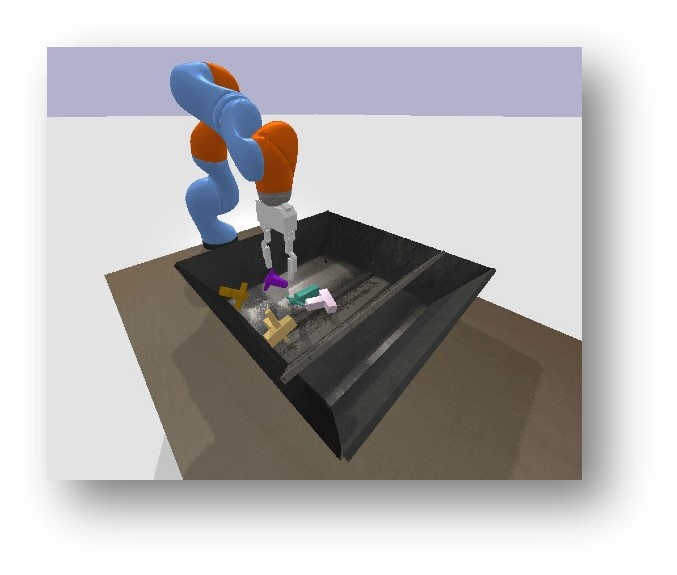

Title 6: Automatic grasping

| Title | Automatic grasping |

| Type | Thesis |

| Supervisor | Ing. Ondřej Novák |

| Possible start | Summer 2021 |

| Required skills | Python, Independent work expected in a form of implementing own ideas with occasional consultation every two weeks or so. (Research topic). |

Topic:

- Continue a work-in-progress project focusing on „how to grasp an object by an industrial robot“. Currently, grasp candidates are established based on their kinematic properties. We would like to add dynamic properties (such as mass, grasp force, friction, …) to the estimation process. Another related topic to be explored is an automated path planner that would find a nearly-optimal path (shortest time), while watching for some constraints (e.g., environmental obstacles or linearity of the movement if required).

Title 7: Development of OPC UA Debugger

| Title | Development of OPC UA Debugger |

| Type | Thesis |

| Supervisor | Ing. Ondřej Novák |

| Possible start | Summer 2021 |

| Required skills | Java or Python |

Topic:

- For connecting industrial devices to each other or connecting these to an external IT software, the OPC UA network protocol is often used. To easily debug device behavior, it is usually handy to create simple software that behaves as a counterpart in the communication (for example a fake robot for testing an control system), that allows the programmer to manually set outputs, read inputs, but also to automatically react to input changes. However, this is often time-consuming. To ease the task, we would like to use existing open-source OPC UA libraries (in Java or Python) and some program libraries for flow programming (such as NodeRED) to develop software that would allow easy creation of such debugging tool.

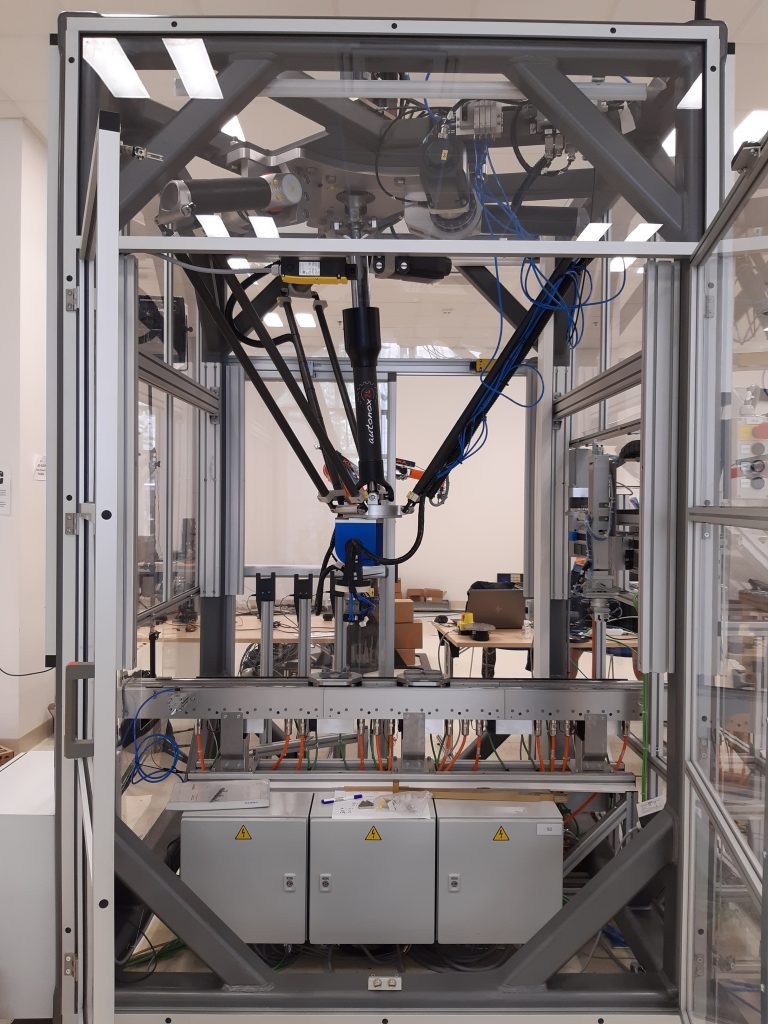

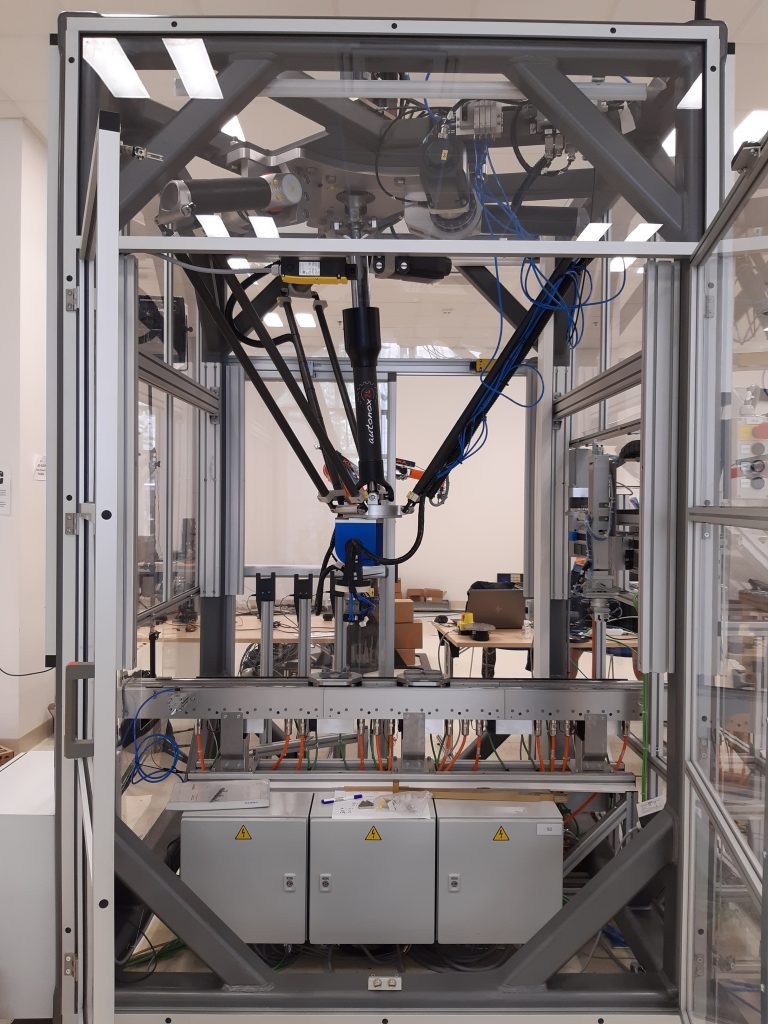

Title 8: Dynamic modelling of a Delta robot

| Title | Dynamic modelling of a Delta robot |

| Type | Student project |

| Supervisor | Baran Alikoc, Ph.D., Pavel Burget, Ph.D. |

| Possible start | Summer 2021 |

| Requred skills | Matlab, Simulink |

Topic:

- Obtain the dynamical model of a 5-DOF industrial Delta robot [1] based on Newton Euler [2] and/or Lagrangian [3] methods. Verify the obtained model through the Simulink model of the robot and compare the simulation results with the real data you get from the physical robot in Testbed (CIIRC).

The kinematic equations of the robot are already derived and the Simulink model using the Simscape library is also developed by the group that you will be working with.

[1] Autonox Robotics GmbH, “Delta robot mechanics RL5-1450-6kg – datasheet” https://en.autonox24.com/products/robots/a 00802.

[2] G. Borchert, M. Battistelli, G. Runge, and A. Raatz, “Analysis of the mass distribution of a functionally extended delta robot”, Robotics and Computer-Integrated Manufacturing, vol. 31, pp. 111–120, 2015.

[3] J. Brinker, N. Funk, P. Ingenlath, Y. Takeda, and B. Corves, “Comparative study of serial-parallel delta robots with full orientation capabilities”, IEEE Robotics and Automation Letters, vol. 2, no. 2, pp. 920–926, 2017.

Title 9: Position control of a Delta robot

| Title | Position control of a Delta robot |

| Type | Student project |

| Supervisor | Baran Alikoc, Ph.D., Pavel Burget, Ph.D. |

| Possible start | Summer 2021 |

| Required skills | Matlab, Simulink, knowledge in control theory |

Topic:

- Design and implement a model-based trajectory tracking control for a 5-DOF industrial Delta robot existing in Testbed (CIIRC). Verify the designed control through the Simulink model of the robot first. Then, implement the control algorithm for the motor drives and compare the simulation results with the experiments performed on the physical robot.

The kinematic equations and a dynamical model of the robot are already derived and the Simulink model using the Simscape library is developed by the group that you will be working with.

[1] Autonox Robotics GmbH, “Delta robot mechanics RL5-1450-6kg – datasheet” https://en.autonox24.com/products/robots/a00802.

[2] B. Siciliano, L. Sciavicco, L. Villani, and G. Oriolo, “Robotics: Modelling, Planning and Control”, Springer, 2010.

[3] Y.-L. Kuo and P.-Y. Huang, “Experimental and simulation studies of motion control of a delta robot using a model-based approach”, International Journal of Advanced Robotic Systems, vol. 14, no. 6, 2017.

Title 10: Force control of a Delta robot

| Title | Force control of a Delta robot |

| Type | Student project |

| Supervisor | Baran Alikoc, Ph.D., Pavel Burget, Ph.D. |

| Possible start | Summer 2021 |

| Required skills | Matlab, Simulink, knowledge in control theory |

Topic:

- Design and implement a model-based force control for a 5-DOF industrial Delta robot existing in Testbed (CIIRC). The task is to limit the force at the end-effector appropriately for hand-guiding. Verify the designed control through the Simulink model of the robot first. Then, implement the control algorithm for the motor drives and compare the simulation results with the experiments performed on the physical robot.

[1] Autonox Robotics GmbH, “Delta robot mechanics RL5-1450-6kg – datasheet” https://en.autonox24.com/products/robots/a 00802.

[2] B. Siciliano, L. Sciavicco, L. Villani, and G. Oriolo, “Robotics: Modelling, Planning and Control”, Springer, 2010.

[3] S.D. Lee, K.H. Ahn, and J. Bok, “Torque control based sensorless hand guiding for direct robot teaching”, In Proc. IEEE International Conference on Intelligent Robots and Systems, pp. 745–750, 2016.

Title 11: Assistive robot for health care

| Title | Assistive robot for health care |

| Type | Internship, thesis |

| Supervisor | Pavel Burget, Ph.D. |

| Possible start | Summer 2021 |

| Required skills | Java, control theory, basic knowledge of robots, experience with collaborative robots is an advantage. Machine vision is an advantage. |

Topic:

- Collaborative robots are capable of being near humans without causing any harm. Application where the robots collaborate with humans actively are, however, still rare. This project is about designing a robotic workplace, where the robot would touch human body at defined places with defined force. The internal force measurement in the robot would be utilized. A separate task would be the identification of the right places where the robot presses on the human body, whereas the localization of the spots would be based on machine vision.

Such a robotic workplace can be extended for further tasks in physiotherapy.

Title 12: Precise measurement and real-time monitoring with Leica laser scanner

| Title | Precise measurement and real-time monitoring with Leica laser scanner |

| Type | Internship, semestral project, thesis |

| Supervisor | Pavel Burget, Ph.D. |

| Possible start | Summer 2021 |

| Required skills | basic knowledge of control theory, basic knowledge of industrial robots, 3D modeling |

Topic:

- Use the Leica laser scanner to accurately target objects in space and get used to working with its respective software. Then use the possibilities of this device for calibration of industrial robots. Subsequently, it is possible to use this device for real-time measurement of a moving point in space. The output of your work will be technical documentation and measurement procedures. A possible extension is the creation of automated tests for measurement.