Pubs and restaurants are facing huge increases in energy prices, and water will also become more expensive in many places. If they were to address the situation drastically, for example by significantly lowering the temperature in the premises, then almost 79 percent of guests would reduce their visits, according to a survey by Prazdroj. Closing the hot kitchen would mean a complete loss of more than a quarter of people. That is why the brewery, in cooperation with experts from the Czech Institute of Informatics, Robotics and Cybernetics (CIIRC) of CTU, in particular from the RICAIP Testbed for Industry 4.0, Microsoft and other technology companies, is looking for cost-saving solutions for pubs using the latest technologies. Together they will measure the energy and water consumption of the tap technology and develop a more environmentally friendly tap. This will provide pubs with energy savings of up to 30 per cent in the future when tapping beer.

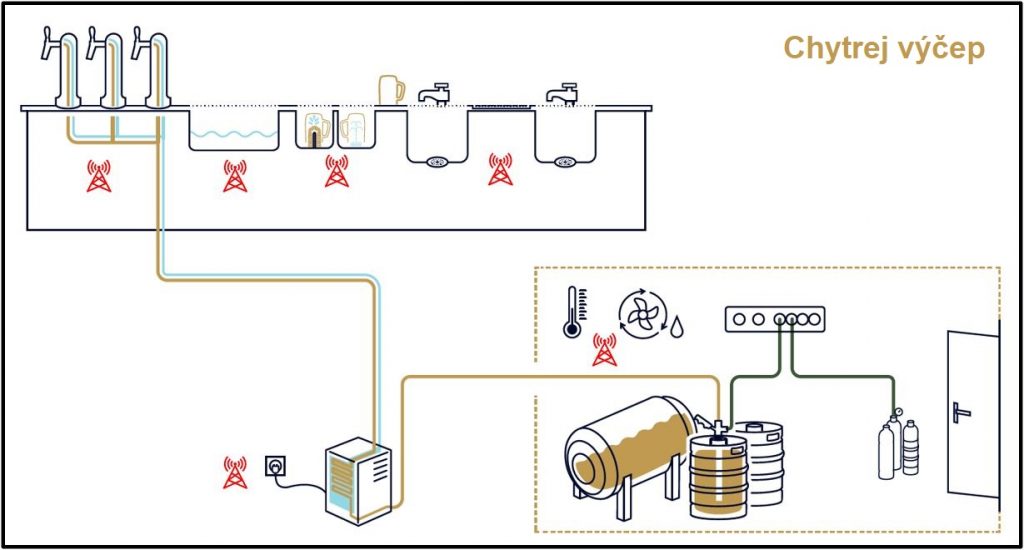

In its efforts to help pubs, Plzeňský Prazdroj is venturing into a completely new area. The traditional beer producer and supplier, together with its technology partners CIIRC CTU, Microsoft, Adastra and Smart Technology, will chip tapping equipment in a total of 45 domestic pubs as part of a project called “Smart Tap / Chytrej výčep” and will collect data on beer flow, water and energy consumption in individual parts of the tap for 12 months. In total, over 1,200 sensors will monitor their operation.

“We initiated the Chytrej výčep project not only to help pubs survive difficult times, but also to bring a solution that will reduce their costs in the long term. By measuring first we get important data. Based on this, we will then innovate the entire tap technology together with our partners and provide it to pubs. All this with the aim of preserving traditional Czech beer culture,” says Tomáš Mráz, Sales Director of Plzeňský Prazdroj.

The project will focus on the entire “journey” of draft beer in the pub. “We will literally X-ray the taproom and map the energy consumption in the entire taproom line, starting with the storage of beer in the cellar or cold storage, through its temperature and heat loss on the way from the keg or tank to the glass on tap. We will also focus on the electricity consumption needed to cool the tub in which the pints are chilled. At the same time, we will monitor and measure water consumption throughout the entire process of caring for the quality of beer and beer glassware. Based on the data we collect, we will then suggest modifications to the taproom that will save the pub owners water and electricity costs. For the guests, nothing will change, the quality of the beer will remain the same, but the pub owner will save up to 30% of energy within the tap,” says Jakub Zaoral, head of the Smart Tap Project from Prazdroj.

Nearly thirty sensors will be used in each measured pub. “We had to develop a comprehensive, tailor-made solution that is also versatile enough. In order to measure different types of variables, such as beer temperature, water flow and, of course, electricity consumption, we connected technologies from several different manufacturers. We can now collect data from a wide range of sensors and send it to the cloud in a form that allows for easy interpretation and further analysis,” says Alexander Lazarov, a researcher at the CIIRC CTU.

The data will be continuously monitored by experts. “We are sending the data collected from the sensors to Microsoft’s Azure cloud platform. We will then use it to create analytical models that will allow us to understand not only what the total water or energy footprint of the beer on tap is, but also which part of the tap has the biggest impact on its level. Our data analysts will then help identify exactly the areas that need to be targeted in the development of a new tap. For simplicity, we are creating a clear graphical interface that allows you to monitor the waveforms of the measured variables,” adds Zdeněk Mistr from Adastra.

Prazdroj is already working on technological innovations to improve the taps, whether it is the possibility of water recuperation, reducing the amount of water used to rinse glasses or the electricity consumption of cooling. “It is absolutely essential for us to maintain the quality of the beer on tap and at the same time help pub owners reduce costs. The measured data will give us an accurate picture of where the key areas that will need to be improved are. The energy consumption of taps and the water flow associated with tap technology and glass care has never been measured to this extent before. At the same time, we will help to reduce the carbon footprint in pubs, so the resulting tap will be as resource-friendly as possible,” adds Ivan Tučník, Prazdroj‘s sustainability manager.

The measurement results will be available in 2023, when many experts expect an even more challenging energy situation than now. But the brewery is already offering pubs a set of recommendations on how to save money. “Just like during the covid, we have reacted immediately and are advising pubs through our sales representatives on how to navigate the energy crisis. Not only with what government assistance applies to them, but also how to effectively manage the economics of the operation or how to work with the equipment and technology they use in the pub so that they don’t waste unnecessarily. In addition, we are developing a conceptual solution that should help them in the long term and permanently,” concludes Tomáš Mráz.

More in media reports: