CIIRC RP95-3D Protective Half-Mask

In just one week in March 2020, the Czech Institute of Informatics, Robotics, and Cybernetics CTU (CIIRC CTU) developed and certified a new personal protective device RP95-3D Protective Half-Mask.

It provides high protection for professionals under the highest clinical exposure.

- The development of the highly professional protective equipment was ready in a week as a not-for-profit initiative.

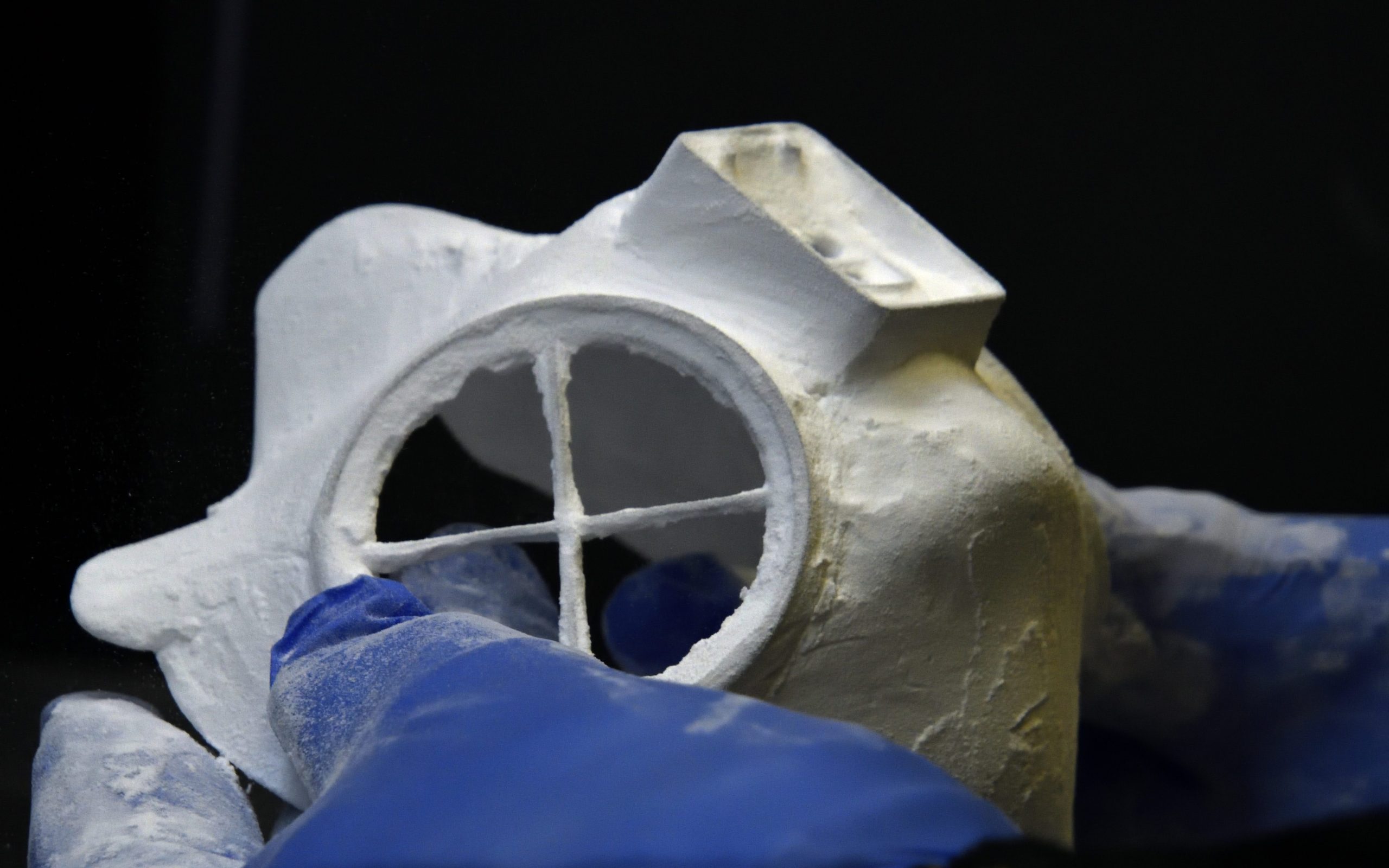

- The mask body printed on 3D HP MJF guarantees top properties. Full CE Certification received – it provides the highest level of protection.

- 3D Data was openly shared worldwide for non-commercial use: downloads in 100+ institutions in 30 countries.

- The 3D technology has been available thanks to the RICAIP Centre.

- The production started within one week with a great support of companies such as Škoda Auto, Siemens and more.

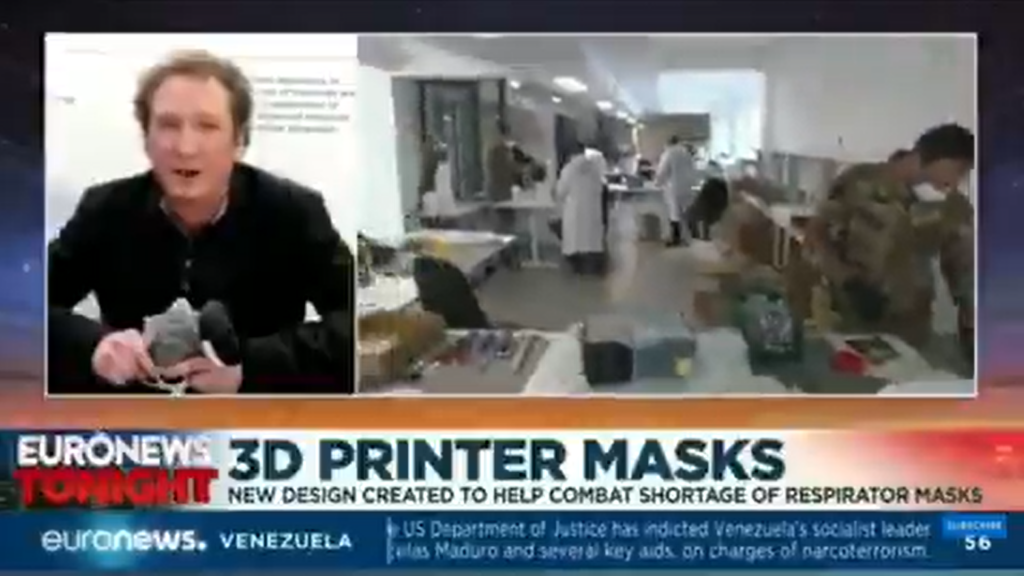

- The media response was enormous – Czech media incl. Czech TV reported intensively as well as Euronews, Reuters, Forbes, Voice of America and more.

- Further development for mass production was done by the spin-off TRIX Connections.

- Awarding: Česká hlava 2020 – Extraordinary award for the scientific contribution solving the problem of the COVID-19 epidemic in a global context – awarded by the Research, Development and Innovation Council (R&D&I Council) of the Government of the Czech Republic.

European Citizen’s Prize 2020: Awarded by the European Parliament in 2020, Ceremony in Prague and Brussels in 2021

The Award of the Engineering Academy of the Czech Republic

Development

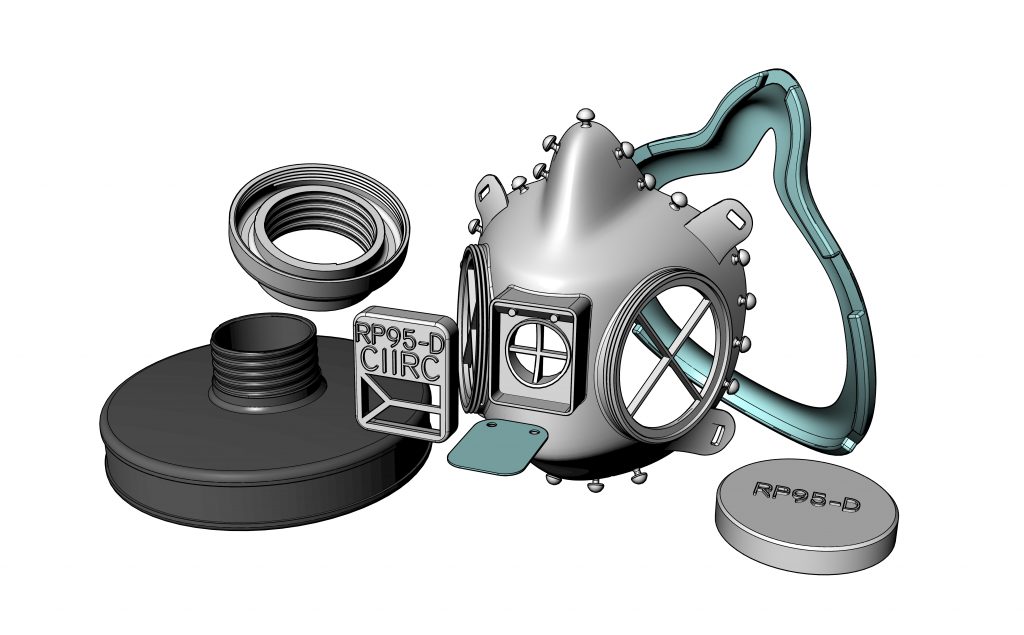

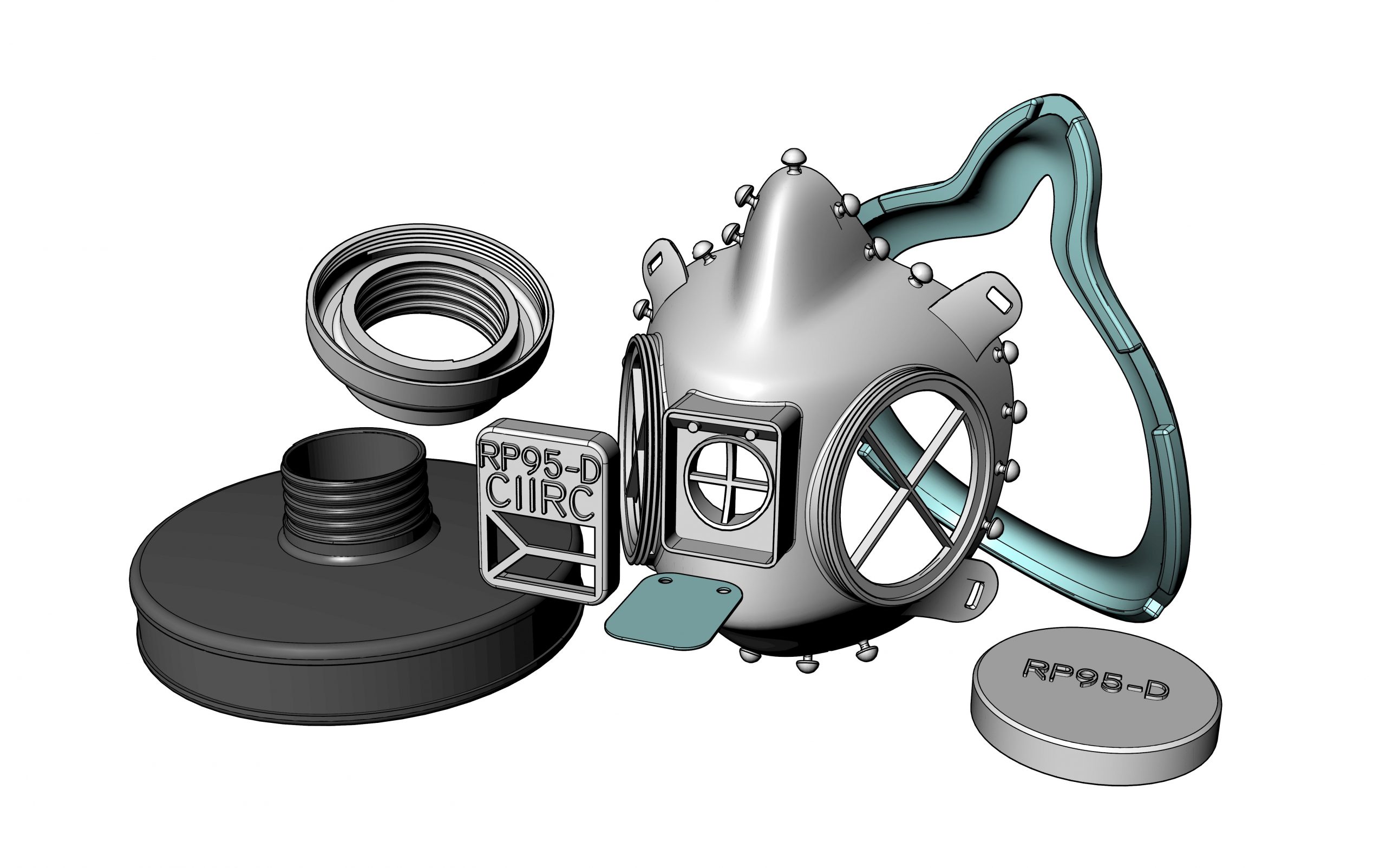

The development was initiated in March 2020 as a not-for-profit initiative to provide protective equipment across Europe after the Covid-19 outbreak. The RP95 is a personal protective device with an exchangeable P3 filter that meets the highest level of protection. The set of a mask body printed on 3D printers and an external filter is certified according to the EN 140:1999 norm and meets the same or higher degree of protection as an FFP3 respirator. The mask can be used repeatedly and has a long-term lifespan. Sterilization is possible in a steam sterilizer (autoclave), at 121°C for 20 min., with alcohol-based disinfection spray (85% ethanol) or with UV radiation. Based on the needs of medical staff in hotspots, it is low weight and has high flexibility. Head grip developed in collaboration with doctors allows safe handling to prevent contamination of the mask from inside.

Cooperation

A team of the Faculty of Electrical Engineering at the University of West Bohemia in Pilsen optimized the silicone exhalation valve design. The CIIRC RP95-3D certification was coordinated with the CzechInvest government agency. The Ministry of Health of the Czech Rep., CTU and CTU start-up, TRIX Connections, signed a memorandum of cooperation on further development. TRIX Connections, the exclusive license holder, managed production companies, research & development. Škoda Auto printed the first trial run of protective masks. 3D Tech helped with the development of a silicone seal moulding form. 3Dees Industries, the official HP 3D Printing distributor in CZ, prepared the production set, helped with the prototype series and also provided additional technical support and coordinated the production & assembly of masks with all HP 3D printer owners in the CZ. Today, masks are being printed on 3D printers in Pilsen, Liberec, by Škoda Auto, Siemens, 3D Tech and 3Dees Industries. The HP Czech Republic provided great support to the manufacturing process.

Data Availability Abroad

Printing data is available for non-commercial use to aid in the fight against the coronavirus pandemic and is provided to all owners of HP MultiJet Fusion 3D printers. Printer owners interested in the data will receive not only the printing files for the actual 3D printing but also instructions on how to assemble the mask and recommendations regarding how to proceed with production according to the Czech pattern. The data is accessible upon entering the HP device serial number and can be used for non-commercial purposes based on a one-month free license.

RICAIP

The protective mask has been developed by the team of the Testbed for Industry 4.0 CIIRC CTU, whose research infrastructure is an integral part of the European Center of Excellence RICAIP. The main objective of RICAIP is to build a unique research facility for the development and testing of innovative solutions for advanced and fully integrated industrial production. The protective mask is the first use case to verify the concept of distributed production.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 857306.

2020 Chronological Summary

| March 13 | The very first idea to develop 3D printed first-class protection respirator mask |

| March 14 | The first 3D model is ready |

| March 17 | The first prototype of the 3D printed respirator mask |

| March 18 | Certification tests initiated |

| March 19 | The university spin-off company TRIX Connection established to carry out the development and technology transfer |

| March 21 | Safety certificate of the product received, issued by the authorized authority |

| March 21 | First 15 pcs delivery (for free) to the Hospital in Prague |

| March 27 | 600pcs RP95 respirator mask delivery (no margin, no profit) to the Czech Ministry of Health |

| March 28 | Samples sent to Italy for free as humanitarian action of the Czech Ministry of Industry and Trade & Czech Ministry of Foreign Affairs |

| March 30 | Website for free 3D print data download www.rp95.cz |

| April 17 | Mass production launched |

| April 20 | Contract on 45000 pcs for Czech Ministry of Health |

Uniqueness

- A unique idea of scientists: The very first 3D printed respirator (half)mask in the world

- Short implementation time: The whole innovation cycle from the first idea, modelling, prototyping, certification & licencing took a week.

- Cooperation between academia and industry: The CTU inventors established spin-off company acting as a natural bridge to industrial ecosystem. More than 40 companies were involved in the supply/value chain.

This contributed to the creation of a highly professional product that meets strict protection criteria. The research team in cooperation with industries managed to prototype the mask in a matter of hours, develop it in days, certify it during 1 week and start producing it in the next week. Data for 3D printing was openly shared with owners of HP MJF devices for non-commercial use and spread to 30 countries around the world. The mask was also put into series production thanks to intensive cooperation with Czech industrial companies.

The development and subsequent production of the RP95 protective half mask is a complex project of the implementation of the initial research idea up to its successful mass production. It is a unique and unparalleled example of technological transfer from academic soil to industrial production in an extremely short time of days and weeks thanks to the enthusiasm and personal commitment of the whole team and collaborators.

Mass Production of RP95-M Model

TRIX Connections focused on the preparation of a half-mask model for mass production and succeeded in adjusting the design for injection molding. TRIX coordinated a consortium of 20 Czech manufacturing companies. In 3 months from the initial idea, the RP95-M mask was ready for production (production capacity up to 50 000 pcs a day), incl. full CE certification. They managed to increase capacity, significantly expand the range of companies that can be involved in the production and lower production costs. The implementation of production is entrusted to the CARDAM company who invested a substantial portion of resources without any state support or certainty of future purchase of manufactured goods by the government.

Impact

EU Registered Scientific/ Technological R&D Result, ID: 23759

See the EU Portal: ID 23759

This case study showed the complete innovation process from idea to tech transfer and was the first demonstrator of the multi-site production concept of the RICAIP centre.

The CIIRC RP95-3D is the certified prototype of a protective half-mask that consist of the high-quality plastic (P12) mask and a replaceable filter (P3R filter certified for EN 143:200). The half-mask was designed to be printed on HP Multijet Fusion 4200 and 5200 series machines. The half-mask has a long-term life-span as it can be repeatedly sterilized.

Protection of medical staff and front-line workers, incl. fire brigade, social workers, testing and hygienic stations

The supply of FFP3 protection at the beginning of the coronavirus crisis was insufficient. Up to 60% of healthcare professionals in the above clinical units are at risk of Covid-19 infection. After 6 weeks of the emergency situation, official statistics showed that 10% of health professionals in the Czech Republic were Covid-19 positive. The infection among healthcare professionals can be effectively dropped down by following the strict FFP3 personal protection. The prompt development of the RP95 mask followed by the whole supply chain organization under the coordination of TRIX Connections showed fast wins in supplying FFP3 protective equipment.

Industries with state-of-the-art robotic equipment

The fast development of the protective RP95 half-mask was possible thanks to tech transfer from academia to industry using novel technologies and approaches. Robotic systems and automation technologies demonstrate the excellent ability of European industry to adapt quickly to emergencies. The RP95 half-mask use-case shows how advanced robotic solutions can flexibly help the transition of locked-down (such as automotive) manufacturing to the production of personal protective equipment.

European independence of production in case of emergency and market failure

The main economic added value for European society and industry is the return of production of critical goods back to the EU, especially in times of emergency. The way in which the EU and thus the Czech Republic relied on production abroad is no longer sustainable. The emergency has clearly demonstrated the need for a distributed decentralized production system that allows European resources to be mobilized quickly. Any open economy and society are vulnerable in times of crisis, and therefore a clear strategy for local capacity transfer based on the principles of distributed but integrated industrial production is needed.

Selection of the Media Appearance

Delivery of masks to Cape Verde

CIIRC CTU Press Releases & Articles